Understanding Diamond Core Drill Bit Maintenance Fundamentals What is diamond core drill bit maintenance and why it matters Keeping diamond core drill bits in good shape means following certain routines that help maintain their cutting power and ov...

VIEW MORE

Material Composition and Its Role in Concrete Drill Bit Longevity The lifespan of a concrete drill bit hinges on its material composition, with premium alloys delivering up to 10× longer service life than standard options in abrasion tests (I...

VIEW MORE

How Diamond Core Drill Bit Technology Enables Superior Performance in Hard Materials Understanding the Diamond-Embedded Design and Cutting Mechanism Diamond core drill bits have industrial strength diamonds built right into their metal body, which ...

VIEW MORE

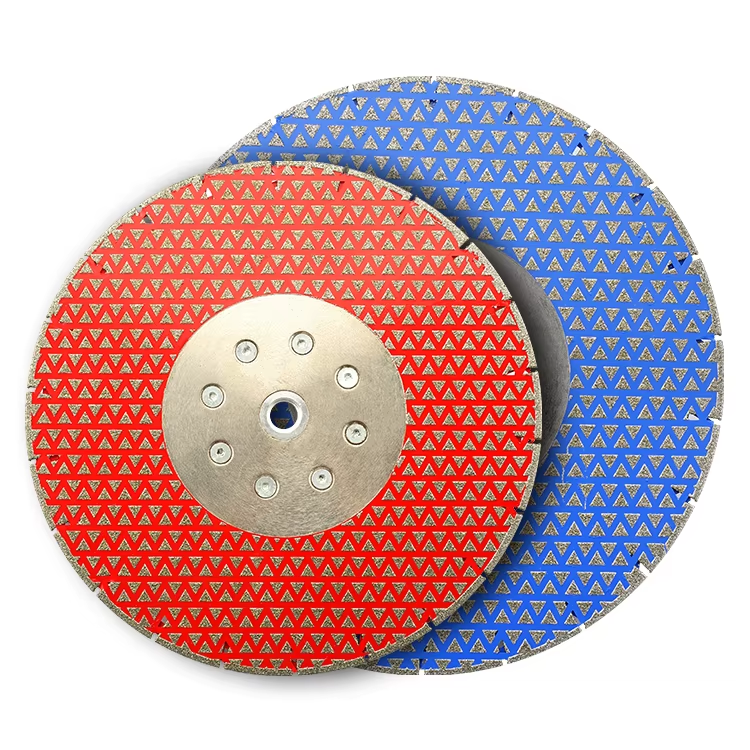

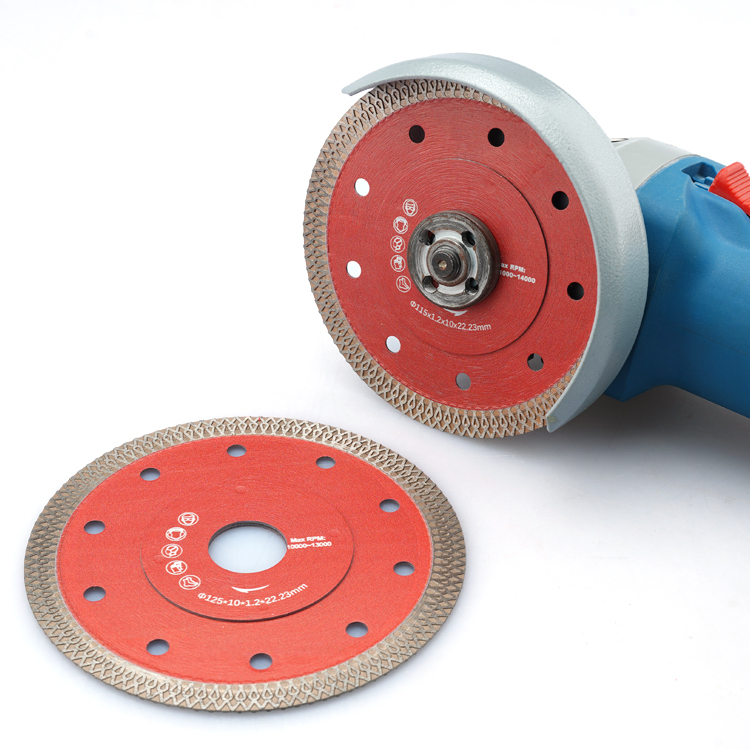

How Diamond Cutting Discs Work for Marble: Technology and Efficiency The Science Behind Diamond Impregnation in Cutting Discs Diamond cutting discs work by using metal bonds that hold synthetic diamonds in place at specific angles, which makes them...

VIEW MORE

How bond hardness (soft, medium, hard) affects diamond cutting disc performance The hardness of a diamond cutting disc's bond plays a big role in how fast those abrasive particles get worn down during use. When we talk about soft bonds, they tend t...

VIEW MORE

The Role of Diamond Abrasives in High-Accuracy Cutting Performance Precision of the cut is achieved through synthetic diamond particles (up to 10,000 HV on Vickers scale) in the disc working layer. These particles are strategically dispersed in a me...

VIEW MORE

Diamond blades use natural rock forming minerals, combined with synthetic diamonds, that are of 10/10 hardness on the Mohs scale to cut the material. Under the surface, each diamond bound by the matrix becomes a tiny chisel, breaking away material a...

VIEW MORE

What Is a Glass Cutting Disc Used For in Edge Refinement? A glass cutting disc is a specialized abrasive tool that refines freshly cut glass edges by controlled material removal. Professionals use them with angle grinders or benchtop machines to: D...

VIEW MORE

Diamond polishing pads leverage industrial-grade diamonds embedded in specialized bond matrices to mechanically refine concrete surfaces. These pads contain precisely sized diamond particles (typically 30-3000 microns) suspended in resin, metal, or ...

VIEW MORE

Material Compatibility of Diamond Drill Bit Sets Diamond drill bit sets offer unmatched versatility for professionals working with hard, brittle materials. Their unique diamond-embedded cutting edges enable precise material removal without compromis...

VIEW MORE

Why Ceramic Tile Diamond Drill Bits Maximize Efficiency Superior Durability for Hard Materials Ceramic tile diamond drill bits stand out for their superior durability, particularly when cutting through hard materials like granite and marble. These d...

VIEW MORE

Understanding Chamfer Bits and Their Applications What Are Chamfer Bits? Chamfer bits are specialized tools designed to create angled edges on various materials, enhancing both their appearance and functionality. These bits feature distinct angled e...

VIEW MORE

Copyright © 2024 by Beijing Deyi Diamond Privacy policy