Diamond blades use natural rock forming minerals, combined with synthetic diamonds, that are of 10/10 hardness on the Mohs scale to cut the material. Under the surface, each diamond bound by the matrix becomes a tiny chisel, breaking away material at contact points as it turns at anywhere from 8,000 to 15,000 rounds per minute (RPM). The technology produces controlled micro-fractures instead of small pieces of rubble, allowing for efficient removal of stone, concrete, and masonry.

Synthetic diamond abrasives achieve 40% higher material removal rates compared to natural diamonds due to consistent crystal structure and optimized thermal conductivity. This efficiency stems from three key mechanisms:

- Fracture-initiated cutting: Diamond edges initiate cracks in brittle materials

- Plastic deformation: Diamond abrasives shear ductile materials like asphalt

- Tribochemical reactions: Frictional heat alters material structure for easier removal

The bond matrix gradually erodes to expose fresh diamond edges, creating a self-sharpening effect critical for maintaining cut quality.

Steel Core, Bond Types, and Diamond Segment Integration

The steel core is rigid to eliminate vibration and cut with precision while the heat vents reduce heat causing the blade to less likely warp. Bond materials — often, metal alloys such as cobalt or nickel — lock in the synthetic diamonds, providing a trade-off between how much of the abrasive is exposed and how well the tool can withstand wear. The softer the bond the easier it is to release new diamond to cut hard material like porcelain whereas the harder the bond the slower the diamond is released to cut soft concrete.

Diamond segments are welded or sintered to the core’s periphery, with concentrations ranging from 10% to 40% depending on the application. Higher diamond density improves lifespan in abrasive masonry, while lower concentrations enhance cutting speed in dense granite.

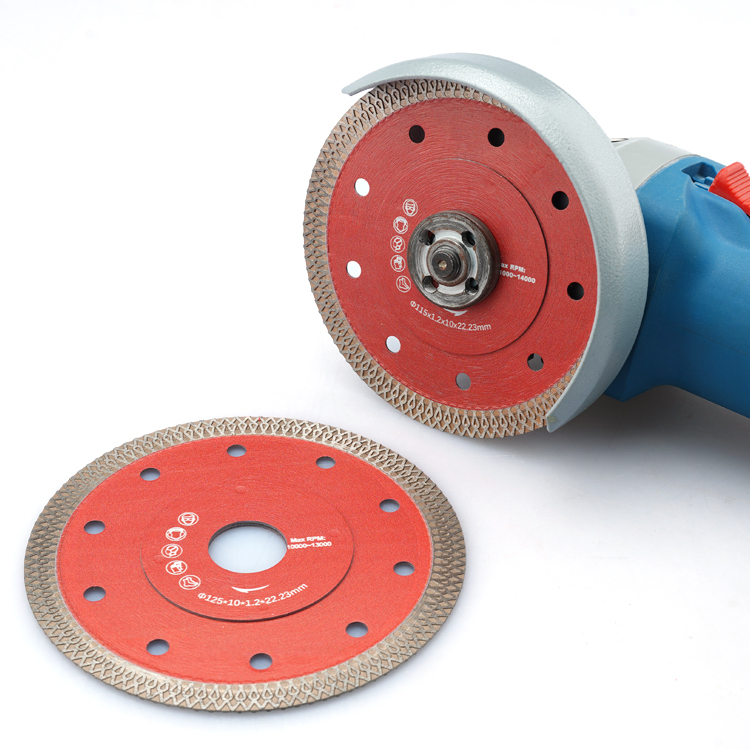

Blade Edge Types: Continuous Rim, Segmented, Turbo, and Viper Designs

- Continuous Rim: Smooth edge for chip-free cuts in tile and glass

- Segmented: Notched edges dissipate heat faster, ideal for dry concrete cutting

- Turbo: Serrated segments with airflow channels for wet/dry masonry cutting

- Viper: Hybrid design with wave-like segments reduces vibration in reinforced concrete

Segmented blades cut 30% faster than continuous rims in granite but produce rougher edges.

Manufacturing Methods: Sintering vs. Laser Welding for Durability

Sintering bonds diamond segments using high heat and pressure, creating porous segments for effective cooling. Laser welding produces 0.2mm precision joints without thermal distortion, extending blade life by 40% in metal-reinforced concrete.

Cutting Mechanism: Micro-Fracturing and Abrasive Grinding in Concrete and Stone

As the disc rotates at 8,000–12,000 RPM, diamond crystals create micro-fractures in concrete and stone surfaces, while the metal bond matrix continuously exposes fresh diamond edges for sustained abrasion. This achieves material removal rates 35% higher than silicon carbide abrasives in granite cutting tests.

The process generates localized temperatures exceeding 600°F, requiring precise bond formulations to prevent premature diamond pull-out in porous materials like limestone.

Performance on Granite, Porcelain Stoneware, and Reinforced Masonry

Granite’s hardness demands diamond discs with soft bronze bonds that erode steadily. Porcelain tile cutting requires ultra-thin (1.0–1.6mm) blades with nickel-cobalt bonds to prevent chipping.

For reinforced masonry:

- 25-30% diamond concentration resists wear from rebar

- Segmented rims dissipate heat 50% faster than continuous edges

- Laser-welded cores reduce harmonic resonance by 40%

Cooling Requirements: Wet vs. Dry Cutting and Thermal Management

Wet cutting systems pump 0.8–1.2 liters/minute of water to:

- Reduce friction temperatures by 300–400°F

- Flush abrasive debris

- Extend blade lifespan 2.5x in marble processing

Dry-cutting discs incorporate radial slots and copper-tungsten bonds. Best practices include:

- Limiting continuous cuts to 45 seconds for 4" blades

- Using RPM-matched angle grinders with thermal protection

- Applying cutting wax on ceramics to reduce dust emission by 70%

Matching Bond Hardness to Material Type

| Material Type | Bond Hardness | Segment Design |

|---|---|---|

| Porcelain Tile | Soft | Continuous Rim |

| Reinforced Concrete | Hard | Segmented with Slots |

| Asphalt | Hard | Turbo Segmented |

Diamond Blades for Concrete, Brick, and Masonry Applications

Segmented-edge diamond cutting discs excel in masonry, offering rapid material removal. Turbo-rim designs reduce vibration in uneven surfaces, improving cut consistency by 18–22%.

Cutting Metal and Rebar: Specialized Diamond Discs

Metal-cutting diamond discs require:

- Laser-welded segments to prevent separation

- Cobalt-rich bonds to resist heat

- Water cooling to minimize sparks

Optimizing Performance on Tile and Stone

Continuous-rim diamond cutting discs provide chip-free cuts on porcelain. For granite, turbo segments enhance cooling. Engineered stone demands low-vibration designs (µ 5 ¼m displacement).

Factors Affecting Lifespan

Excessive temperatures (above 350°F/177°C) degrade the bond matrix, causing premature diamond loss. Operating speeds beyond rated limits increase heat buildup by 19–27% per 1,000 RPM overage.

| Material Type | Avg. Wear Rate Increase | Thermal Conductivity (W/m·K) |

|---|---|---|

| Reinforced Concrete | Baseline | 1.7 |

| Porcelain Tile | 38% Higher | 1.2 |

| Granite | 22% Higher | 2.8 |

| Steel-Rebar Embedded | 63% Higher | 45.0 |

Modern bond systems use thermally stable metallic alloys that maintain diamond retention longer.

Best Practices for Extending Disc Life

- Match tool speed to disc ratings—a 10% RPM reduction increases lifespan by 15–18%

- Break-In New Discs with 5–10 shallow cuts (µ 0.5" depth)

- Use Wet Cutting to reduce temps by 260–300°F

- Clean segments after use—impacted material increases friction by 41%

Proper heat management and material-specific disc selection reduce replacement costs while maintaining cutting consistency.

FAQ

What are diamond cutting discs made of?

Diamond cutting discs are composed of synthetic diamonds bound together through metal matrix bonds, commonly made of cobalt or nickel alloys.

How do diamond cutting discs self-sharpen?

The matrix holding the diamonds gradually erodes during use, exposing fresh diamond edges, thus creating a self-sharpening effect.

What materials can diamond cutting discs cut?

They can cut hard materials like stone, concrete, and masonry, and specific designs can handle metal and rebar.

How does bond hardness affect cutting performance?

Softer bonds release diamonds quickly for cutting hard materials, while harder bonds hold diamonds longer for cutting softer materials.

Table of Contents

- Steel Core, Bond Types, and Diamond Segment Integration

- Blade Edge Types: Continuous Rim, Segmented, Turbo, and Viper Designs

- Manufacturing Methods: Sintering vs. Laser Welding for Durability

- Cutting Mechanism: Micro-Fracturing and Abrasive Grinding in Concrete and Stone

- Performance on Granite, Porcelain Stoneware, and Reinforced Masonry

- Cooling Requirements: Wet vs. Dry Cutting and Thermal Management

- Matching Bond Hardness to Material Type

- Diamond Blades for Concrete, Brick, and Masonry Applications

- Cutting Metal and Rebar: Specialized Diamond Discs

- Optimizing Performance on Tile and Stone

- Factors Affecting Lifespan

- Best Practices for Extending Disc Life

- FAQ