Ama-diamond blade asebenzisa amaminerali emvelo akha amatshe, ahlanganiswe namadayimane enziwe ngomshini, anobulukhuni obungu-10/10 esikalini sikaMohs ukusika impahla. Ngaphansi komhlaba, idayimane ngalinye elihlanganiswe yi-matrix liba umqwayi omncane, uhlukanisa izinto lapho zixhumana khona njengoba liphenduka noma kuphi phakathi kuka-8.000 no-15.000 RPM (izingqimba ngomzuzu). Lobu buchwepheshe bukhiqiza ama-micro-fractures alawulwayo esikhundleni sezingcezu ezincane zemfucumfucu, okuvumela ukususwa ngempumelelo kwetshe, ukhonkolo, nokwakhiwa.

Ama-abrasives edayimane ayindilinga athola amazinga aphezulu angama-40% okususa izinto uma eqhathaniswa namadayimane emvelo ngenxa yesakhiwo sekristalu esihambisanayo nokuqhuba ukushisa okuhle. Lokhu kusebenza kahle kuvela ezenzweni ezintathu ezibalulekile:

- Ukuqhekeka okuqalwa ukuqhuma : Imikhawulo yedayimane idala imifantu ezintweni eziphukile

- Ukuguqulwa kwepulasitiki : Izinsimbi ezihlabayo zedayimane ziyasika izinto eziqinile ezifana ne-asphalt

- Ukuphendula kwe-tribochemical : Ukushisa kokushayisana kushintsha ukwakheka kwezinto ukuze kususwe kalula

I-bond matrix iyancipha kancane kancane ukuze iveze imiphetho yamadayimane amasha, okudala umphumela wokuzicija obalulekile ekugcineni ikhwalithi yokusika.

Insimbi, Izinhlobo Zokubopha, Nokuhlanganiswa Kwesigaba Sikadayimane

Umgogodla wensimbi uqinile ukuze uqede ukudlidliza futhi usike ngokunemba kuyilapho izimbobo zokushisa zinciphisa ukushisa okwenza ukuba i-blade ingabi namandla okuguquguquka. Izinto zokubopha ngokuvamile, ingxubevange yensimbi efana ne-cobalt noma i-nickel ibopha amadayimane enziwe ngomshini, inikeze ukuhwebelana phakathi kokuthi ingakanani into yokuchoboza etholakala nokuthi ithuluzi lingamelana kanjani nokugqoka. Lapho isibopho sithambile kuba lula ukukhulula idayimane elisha ukuze kusikwe izinto ezinzima ezifana ne-porcelain kanti lapho isibopho siqinile kuba lula ukukhulula idayimane ukuze kusikwe ukhonkolo othambile.

Izingxenye zedayimane zishiselwa noma zifakwe i-sinter emaphethelweni enhliziyo, ezinokuhlushwa okuvela ku-10% kuya ku-40% kuye ngokuthi kusetshenziswe ini. Ukuqina kwedayimane okuphezulu kuthuthukisa isikhathi sokuphila kokubunjwa kwe-abrasive, kuyilapho ukuqina okuphansi kuthuthukisa ijubane lokusika egranite eliqinile.

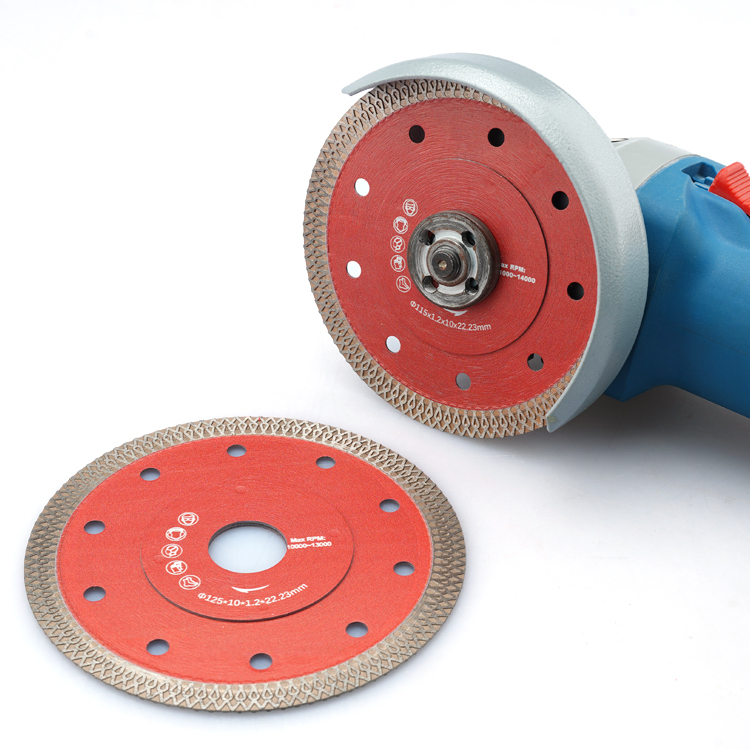

Izinhlobo Zomkhawulo Wama-blade: Umklamo Wokuqhubeka Wokuhamba, Ohlukanisiwe, Oguquguqukayo, Nowe-Viper

- Umngcele oqhubekayo : Umphetho ogudile wokusika ngaphandle kwezingcezu zamathayili nengilazi

- Ukuhlukaniswa : Imikhawulo enama-notch idlulisa ukushisa ngokushesha, ilungele ukusika ukhonkolo owomile

- I-Turbo : Izingxenye ezihlotshisiwe ezinemizila yomoya yokusika ukwakhiwa kwe-wet/dry masonry

- Izinyoka : Ukwakheka kwe-hybrid okuhlanganisa izingxenye ezinjengamagagasi kunciphisa ukudlidliza kukakhonkolo oqinisiwe

Ama-blade ahlukanisiwe asika ngokushesha ngo-30% kunama-rim aqhubekayo egranite kodwa akhiqiza imiphetho engakhudlwana.

Izindlela Zokukhiqiza: Ukuxubha noma Ukushisela Nge-Laser Ukuze Uhlale Isikhathi Eside

Ukuhlunga ibopha izingxenye zedayimane kusetshenziswa ukushisa okuphezulu nengcindezi, kwakheke izingxenye ezixekethile ukuze kuphole kahle. Ukuhluhloba ngolayitha ikhiqiza amalunga anembile angu-0.2mm ngaphandle kokuguqulwa ukushisa, okwandisa ukuphila kweblade ngo-40% kukhonkolo oqiniswe ngensimbi.

Indlela Yokusika: Ukuqhekeka Okuncane Nokugqwala Okuhlabayo Ekhonkritini Nasetsheni

Njengoba i-disc ijikeleza ngo-8,00012,000 RPM, amakristalu edayimane akha ama-micro-fractures ebhethini nasetsheni, kuyilapho i-metal bond matrix iqhubeka ibeka imiphetho emisha yedayimane ukuze iqhubeke nokuqhekeka. Lokhu kufinyelela amazinga okususa izinto aphakeme ngama-35% kunama-abrasives e-silicon carbide ekuhlolweni kokusika igranite.

Le nqubo iveza amazinga okushisa angaphakathi edlula u-600°F, okudinga amafomu aqondile okubopha ukuvimbela ukudonsa idayimane ngaphambi kwesikhathi ezintweni ezixubene njengetshe lomquba.

Ukudlala Ngegranite, I-Porcelain Stoneware, Ne-Masonry Eqinisiwe

Ubukhulu be-granite budinga ama-disc edayimane anezibopho zethusi ezithambile ezibolayo. Ukusika ithayela le-porcelain kudinga ama-blade amancane kakhulu (1.01.6mm) anezibopho ze-nickel-cobalt ukuvimbela ukuchotshozwa.

Ukuze ukwakhiwa kwezindonga eziqinisiwe:

- 25-30% idayimane lokuhlushwa ukumelana ukugqoka kusukela rebar

- Ama-rim agqagqene asakaza ukushisa ngokushesha ngo-50% kunama-rim aqhubekayo

- Amakhodi alukiwe nge-laser anciphisa ukuzwakala kwe-harmonic ngo-40%

Izidingo zokupholisa: Ukusika okumanzi noma okomile nokuphathwa kokushisa

Izinhlelo zokusika ezimanzi phonsa amanzi angu-0.81.2 litres/minute ukuze:

- Nciphisa amazinga okushisa okuxubana ngo-300°F

- Izinsalela ezibhubhisayo

- Yandisa isikhathi sokuphila se-blade 2.5x ekucutshungweni kwe-marble

Ama-disc okusika okomile ukufaka izikhala ezishisayo kanye nezibopho zethusi ne-tungsten. Imikhuba emihle ihlanganisa:

- Ukuvimbela ukusika okuqhubekayo kube imizuzwana engu-45 ngama-blade angu-4"

- Ukusebenzisa ama-grinder angukhiye afanayo we-RPM ngokuvikelwa okushisayo

- Ukusebenzisa i-wax yokusika ku-ceramics ukunciphisa ukungcola kothuli ngo-70%

Ukufanisa Ubunzima Bokuxhuma Nohlobo Lwezinto

| Uhlobo Lwezinto | Ubunzima Bokuxhuma | Ukwakheka Kwezingxenye |

|---|---|---|

| Ilepha yeporcelain | Esihlahleki | Umngcele oqhubekayo |

| Ibhethone eliyimkisa | Kunzima | Ihlukaniswe ngama-slots |

| Izindwangu zokwakha | Kunzima | I-Turbo Ihlukaniswe |

Ama-diamond blade okusetshenziswa kukhonkolo, izitini, kanye nokwakhiwa kwezindonga

Ama-disc okusika idayimane anesiqephu esihlukanisiwe ahamba phambili ekufakeni udonga, enikeza ukususwa okusheshayo kwezinto. Imiklamo ye-turbo-rim inciphisa ukudlidliza ezindaweni ezingalingani, ithuthukise ukuvumelana kokusika ngo-1822%.

Ukusika Izinsimbi Nezinhlaka: Amadayimane Akhethekile

Ama-disc edayimane okusika izinsimbi adinga:

- Izingxenye ezishiselwe nge-laser ukuvimbela ukuhlukaniswa

- Izibopho ezicebile nge-cobalt ukuze zimelane nokushisa

- Ukupholisa ngamanzi ukuze kuncishiswe izinhlansi

Ukwenza Ngcono Ukusebenza Kwezingodo Namatshe

Ama-disc okusika idayimane anesiqephu esiqhubekayo anikeza ukusika okungenawo ama-chip ku-porcelain. Ukuze kuqiniswe ukuphoqa, ama-turbo-segment agcina ama-granite epholile. Amatshe enziwe ngobunjiniyela adinga ukwakheka okuphansi kokudlidliza (ukuhunyushwa kwe-μ 5 1⁄4 m).

Izici Ezithinta Isikhathi Sokuphila

Amazinga okushisa aphezulu (angaphezulu kuka-177°C) enza ukuba i-bond matrix iwohloke, okubangela ukulahleka kwedayimane ngaphambi kwesikhathi. Izinga lokusebenza elingaphezu kwemingcele ebekiwe likhulisa ukushisa okungu-1927% nge-1000 RPM.

| Uhlobo Lwezinto | Isilinganiso. Ukwanda Kokusebenzisa | Ukuqhuba ukushisa (W/m·K) |

|---|---|---|

| Ibhethone eliyimkisa | Isigaba Esikhulu | 1.7 |

| Ilepha yeporcelain | 38% Ephakeme | 1.2 |

| Igranite | 22% Ephakeme | 2.8 |

| Izinsimbi Ezisongwe Nge-Ribbar | 63% Ephakeme | 45.0 |

Izinhlelo zanamuhla zokuhlanganisa izinto zisebenzisa ama-alloys ensimbi azinzile ukushisa agcina idayimane lihlala isikhathi eside.

Izindlela Ezinhle Zokwelula Isikhathi Sokuphila Kwediski

- Ukufanisa isivinini sethuluzi namazinga e-disc ukunciphisa ama-RPM angu-10% kwandisa isikhathi sokuphila ngo-1518%

- Ama-disc Amasha Aphukile nge-510 izingcezu ezingajulile (μ 0,5 "ukujula)

- Sebenzisa Ukuzisika Ngamanzi ukunciphisa amazinga okushisa ngo-260300°F

- Hlanza izingxenye ngemva kokusetshenziswa izinto ezishaywayo zandisa ukuchoboza ngo-41%

Ukuphathwa kahle kokushisa nokukhethwa kwe-disc ethile yokwakha kunciphisa izindleko zokushintsha kuyilapho kugcinwa ukuvumelana kokusika.

Imibuzo Evame Ukubuzwa

Zenziwe ngani iziqeshana zedayimane?

Ama-disc okusika amadayimane akhiwa amadayimane enziwe ngomshini aboshwe ndawonye ngama-matrix bond ensimbi, ngokuvamile enziwe nge-cobalt noma i-nickel alloys.

Ama-disc okusika amadayimane azishintsha kanjani?

I-matrix egcina amadayimane iyawohloka kancane kancane lapho isetshenziswa, iveza imiphetho emisha yedayimane, ngaleyo ndlela idale umphumela wokuzicija.

Zingapi izinto ezinakuyishaywa ngamaDiamond Cutting Discs?

Zingasika izinto ezinzima njengetshe, ukhonkolo, nokwakhiwa, futhi imiklamo ethile ingasebenza ngensimbi ne-armor.

Ubunzima be-bond bunamuphi umthelela ekusebenzeni kokusika?

Ama-bond athambile akhulula amadayimane ngokushesha ukuze kusikwe izinto ezinzima, kuyilapho ama-bond aqinile egcina amadayimane isikhathi eside ukuze kusikwe izinto ezithambile.

Uhlu Lwezinto Eziqukethwe

- Insimbi, Izinhlobo Zokubopha, Nokuhlanganiswa Kwesigaba Sikadayimane

- Izinhlobo Zomkhawulo Wama-blade: Umklamo Wokuqhubeka Wokuhamba, Ohlukanisiwe, Oguquguqukayo, Nowe-Viper

- Izindlela Zokukhiqiza: Ukuxubha noma Ukushisela Nge-Laser Ukuze Uhlale Isikhathi Eside

- Indlela Yokusika: Ukuqhekeka Okuncane Nokugqwala Okuhlabayo Ekhonkritini Nasetsheni

- Ukudlala Ngegranite, I-Porcelain Stoneware, Ne-Masonry Eqinisiwe

- Izidingo zokupholisa: Ukusika okumanzi noma okomile nokuphathwa kokushisa

- Ukufanisa Ubunzima Bokuxhuma Nohlobo Lwezinto

- Ama-diamond blade okusetshenziswa kukhonkolo, izitini, kanye nokwakhiwa kwezindonga

- Ukusika Izinsimbi Nezinhlaka: Amadayimane Akhethekile

- Ukwenza Ngcono Ukusebenza Kwezingodo Namatshe

- Izici Ezithinta Isikhathi Sokuphila

- Izindlela Ezinhle Zokwelula Isikhathi Sokuphila Kwediski

- Imibuzo Evame Ukubuzwa