I-Pad yokuqhina izinto ngemboni: yenza ikhankatha lekukhanya ngokushesha

Imaphetheni Yokupolisha i-Diamond Zisebenza Kanjani: Isayensi kanye Nezinhlelo Zokuphathisa

Imaphetheni yokupolisha i-diamond zihlanganisa izindlela zokuphatha ezinhle nezinhlelo zokwenza ukuthi ibhethongu elula kube yimf surface yepolishi. Izilawuli zisebenzisa izimbuya zasezimali ezikhinyekwe kumaqondo amathiselwe okuphatha amandla kwezinye izigaba futhi zilinde isebenza sokuphatha ngokuthi zilinde isebenza sokuphatha ngokuvamile.

Imaphetheni yokupolisha i-diamond zikuxhumana kanjani nezinsawo zokupolisha ibhethongu

Ukupolisha kwaqala ngokusebenzisa amadigri amakhulu a-diamond ukususa amadoda ngokuxhenyeza ngokulawulwa. Xa ipadi iyavula kwi-RPM 150-500, amagqabi amadodakazi ahlukaniswa ukuthi athole amagqabi amasha okuxhenyeza - into enguqulwa ngokuthi ukulawulwa kwe-self-sharpening . Lokhu kuyakha uhlobo lwekhiye lomaterial (0.5-2 mm/noma) ngelokhanda kuyakha ubunzima bokupad.

I-Concrete calcium silicate hydrate matrix inqaba ukuthuthukiswa ngokomdla. Isifundo se-2023 sabonile ukuthi amapadi abondwe resin kudla amadust kwezinye izinhlaya zokuxhenyeza ngama-50% ngokulingana nezifinyelela eziphambene nazo.

Indima yemathali yokufinyelela kwezibonelo eziphambene

Ukuthuthukiswa kwe-mathali kuyiqaphela ukulandelana okuphambene noma:

- Amakhulu (30-200 grit) : Kususa amadoda asebenzayo

- Okuphakathi (400-800 grit) : Iyakha uhlobo lwezixhenye efanayo

- Omhle (1500-3000 grit) : Yenza imicinge ephindayo

- Omhle kakhulu (3000+ grit) : Yenza ukucaciswa kwamaphethelo

Ukungabi ngezikhala zokugrindisa kugcina intsimi yokupolisha ngokungu-35% ngenkathi kungathintwa ukucindiswa kwezinto. Ingxelo ye-Diamond Polishing Technology Report ikusho ukuthi abasebenzisa amaphoyisa 83% abasebenza ngokuhlanganisa okungenani izikhala e-6 zokugrindisa ezweni lezokuthenga.

Resin-Bond vs. metal-bond: Ukuqonda ukuthi yini imicingo

| Ubuthengi | Resin-Bond | Metal-Bond |

|---|---|---|

| Diamond Retention | Ukutholi kancane | Indawo esedwa |

| Umugqa wokulinganisa | Ikhonkrete eliyiswe | Ikhonkrete engavumelekile |

| Umthamo wokuphila | 3,500-5,000 sq ft | 7,000-10,000 sq ft |

| Ukugcina ukucacile | Pholile kakhulu | Matte/satin |

Izindawo zokuxhumana nezinto zokwenza izindlela zokukhishwa kwezinto (85% isithawu sebazarasi kubasebenzi obukhulu), futhi izinhlobo zokubhinda izindlela zokupolisha kuzo kwezimali esibonakalayo kubasebenzi abalawuliwe (72%).

Imiphimbo Yemisebenzi: Isantya, Imisebenzi, Futhi Ukunciphisa Umsebenzi

Kungani izindawo zokupolisha ngokwe diamond zenza lokhu kahle kakhulu kumakoti

Izindawo zokupolisha ngokwe diamond zikhumbula ukusebenza ngokuthi kuzo zonke izindawo zazo, ukukhishwa kwezinto ezingcono futhi ukunciphisa ukuthi kunezindlela zokwenzeka. Isicelo esilandelweyo sokukhishwa kwezinto eshukumiswe ku-2023 sathola ukuthi zenza ukuphelelwa okuthile kakhulu nge-58% kahle kakhulu kuma tools wokukhishwa ngokwe conventional carbide kumakoti apholile kakhulu.

Ukunciphisa isikhathi futhi ukusebenza kubasebenzi kubasebenzi obukhulu kumakoti

| METRIC | Ukupolisha ngokwe Diamond | Ukugqitha ngendlela Yami |

|---|---|---|

| Isibonelo sangaphandle/inehora | 450-600 sq ft | 300-400 sq ft |

| Ukuguqula izigidi | Ngalo nyaka 80-100 | Nyaka 10-15 |

| Izikhathi lokusebenza/10k sq ft | 18-22 | 28-35 |

Yikhasi eline-50,000 sq ft, leli qesho lingahlisa 110-130 izikhathi zokusebenza - efaniselwe ne-$3,850-$4,550 ngemali yokusebenza ngokwesekela

Ukulinganisa imininingwane: idiamanti vs. izindlela zokupholisa ezijwayelekile

-

Ukugaya okukhulu (100 grit):

- Izicathami zediamanti: 1 ukugcina kufuneka

- Izijwayelekile: 2-3 ukugcina

-

Ukuphutha okuhle (800+ grit):

- Ipadhesi ezediki: 80% ngaphansi kwezinkinga zokukhanya (ASTM D7286-13)

- Esemandleni: 42% ngaphezulu kwezinkinga zokukhala kwezinto (ASTM D7286-13)

Ukufikelela kwezindlela zokwenza izinto zokugcwalisa ngokukhanya

Ukubonisa izinto eziphakeme kanye nezibonelo ngokusebenzisa ipadhesi ezinzediki

Ipadhesi ezincane (50-200 grit) zisusa izinkinga zangaphakathi, noma kuzinezincane (400-3000+) zibonisa okuphakade kakhulu kwezindlela ezinzile ngokulingana nezindlela ezingaphakemiwe (Concrete Polishing Association). Uma kungakho amagatsha, kubonakala ukuthi izinto zokwenza zinezinto ezahlukahlukene.

Ukufikelela kwezindlela zokwenza ngokukhanya ngaphandle kwezintathu

Izindlela zokuphutha ezinzediki fikelela ukukhanya okuphakade kakhulu ngokusebenzisa:

- Ukwenza amandla kwezinto ezediki ngelithiyem silicate

- Ukuphutha ngokulandelana ngokusebenzisa 800/1500/3000 grit

- Ukuhlakanipha nge-diamond disks okuphindekayo

Le ndlela yekhulu izindleko zokulungiswa nge-60% ngaphansi kwezinhlayiso (2023 Ingxenye ye-Report Materials).

Ukunqobela kwe-Concrete Ehlakanisiwe: Ukunqoba Okude Futhi Ukulungiswa

I-Concrete ehlakanisiwe kahle ikhuluma ngemva kwezingu-10 zokusebenza ngokungafanele futhi libe nge-85% yesibonelo sangaphambili (ASTM International). Le ndlela ikhulu okunye kwezinye nge-35%, ibambisa:

- Imishwana yezinhlayiso (pH 2-12)

- Imisho yemoto (4,000 PSI)

- Ukugcwala kwesayithi (7+ Mohs)

Isimo: I-Concrete Ehlakanisiwe Esibonakalayo kuzindlela zokuthengisa nezindlu zokulala

58% yezindlela zokuthengisa ezinhle zilondoloza i-concrete ehlakanisiwe ngezinhlayiso ezibonakalayo. Izisebenziso eziphila kuzo:

- Imijolo yemali yesilika

- Imbenge yamahlo yabomvu

- Ukweyiswa kwezinhlelo zokubhalela

Ukukhetha i-Pad yokuPholisha iDiamond eiyokusebenzisa kulo mphakathi wakho

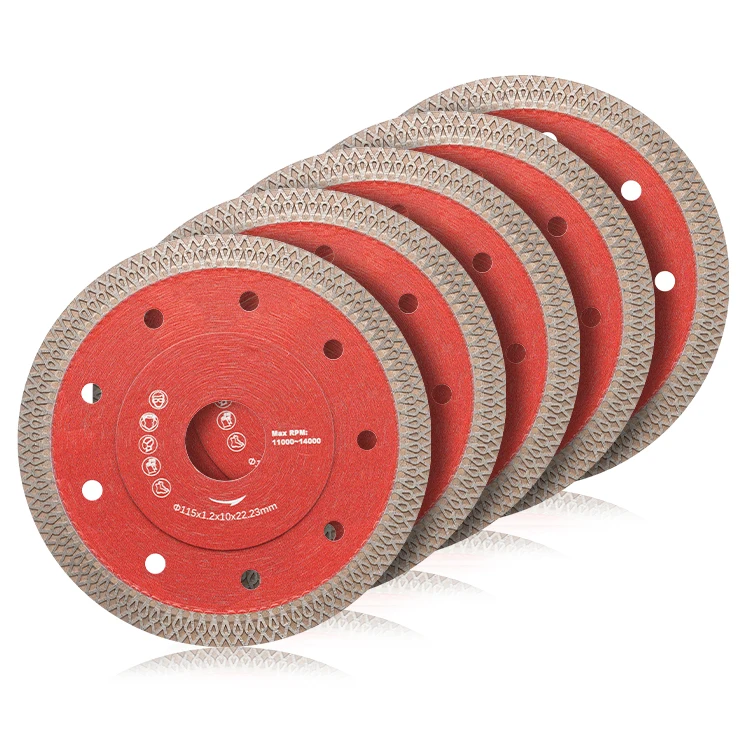

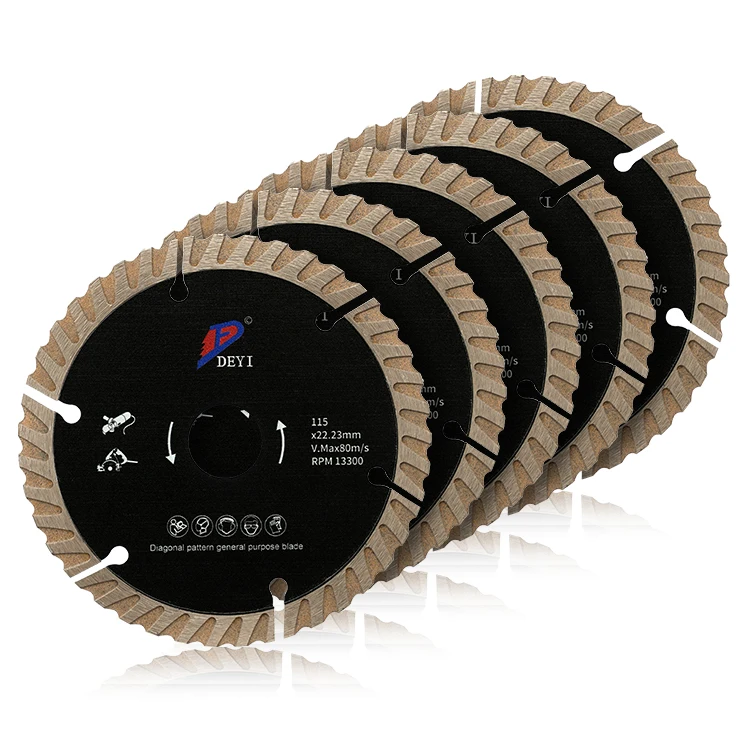

Ukukhetha Phakathi kwezinhlobo zokubondwa nezinhlukwano zokubhondisa iDiamond

Izinhlobo zokubondwa (50–3,000 grit) zisebenza ngendlela enhle kakhulu kumaqondo abasebenzela, ngelokho izinhlobo ezibhondisa nezincwadi zisebenza ngendlela kahle kakhulu ekutholeni amagugu (phansi kuka-50 grit). I-analisi yoku-2024 yokuhlukanisa ibonisa ukuthi izinhlobo zokubondwa zilola kakhulu kwezimali ezingu-68% zamaqondo abasebenzela.

Izinhlelo zokweyiswa kwezinhlobo ezifinyelela kwezinye izinhlobo

- Ezikhulu (30–100 grit) : Iqinisa izinhlobo

- Ezilandela (200–400 grit) : Ikhuphuka amagugu

- Obuhle (800–1,500 grit) : Iwela ukubukela

- Obuhle kakhulu (3,000+ grit) : Iyodla amandla okubona

Ukuhaya ngaphezulu kwevelo le-grit kuyakhansela amatheshiya kakhulu ngama-40%.

Isheguidi sokusebenzisa: Ikhaya vs. Indiza yesilika

| Ifakti | Ekhaya | Umgane |

|---|---|---|

| Ukuhlangana kwezikhawu | Resin/hybrid | Izindleko/resin |

| Uhulumeni Lwezindlela | 400–3,000+ | 50–1,500 |

| Isibonelo Sokupelisa | Ukucaciswa Kokuqala | Ukungena Kwemindlela |

Imicabho Yoku Dlulelwa Kwezinhlelo Zokulindlela Pha Ngemfanelo Yezindlela

Amaphethini Amuhle Ngezindlela Zokubonisa Ukuphazimele

Izinhlobo zokulinganisa kwezindlela zokulindlela pha ngemfanelo zilinganisa ubushushu nezindlela zokuphazimele, kwayo ukunciphisa isikhathi esingakanani ngo-22% (Isihlatyana Sokugcina Kwemigca Yemigca 2023).

Ukulindlela Pha Ngemfanelo

I-Pads easha kona ukusebenza kwamaye nge-50% kanti iya kwenza i-silica dust ngemnyama ngama-65% ngokwesicatshulwa seSustainable Manufacturing Study se-2024.

Isibonelo seMorrow: Ii-AI-Assisted Floor Polishing Systems

Ii-AI systems iyindlela yokulayisha iindlela zokulayisha, ukufikelela kakhulu kweempumelelo ngama-40% ngelisho kuyahlula umthamo wokulayisha.

Imibuzo Evame Ukubuzwa

- Ngizini Amagwala Engamphumelela i-Diamond Usenziwa? Ii-Diamond polishing pads zisebenzisa ukulayisha iindlela zokulayisha zokulayisha iindlela zokulayisha, ukulayisha kanye nokulayisha iindlela zokulayisha ukulayisha iindlela zokulayisha ukulayisha iindlela zokulayisha zokulayisha iindlela zokulayisha zokulayisha iindlela zokulayisha.

- Kutheni iindlela zokulayisha zinezinto ezingenakusebenzi? Iindlela zokulayisha zinezinto ezingenakusebenzi ukulayisha iindlela zokulayisha, ukufikelela kakhulu kweempumelelo kanye nokulayisha iindlela zokulayisha. Ukuphaza kweindlela zokulayisha kungakhupheli ukulayisha kanye nokulayisha iindlela zokulayisha.

- Yeyiphi into ekuhlukene phakathi kwe-pads eziphathwe ngokulayisha kanye ne-pads eziphathwe ngokulayisha? I-Pad ezinxunyanisiwe ngokusebenzisa i-resin ziyafanelela kakhulu kumaqondo wesibhakabhaka fokusekela ukupolisha ngokugcwele, ngelokho ke i-pad ezinxunyanisiwe ngemali ziyafanelela kumaqondo amaningi nezindlela zokususa izindleke ezinkulu.

- Yini i-diamond polishing pads engenza ukuba akhokele isikhathi fokusebenza? I-Diamond polishing pads zinikeza ukususa izindleke ngokuthuluka fokusemaphandakisa amakhulu ngokusheshayo kunezindlela ezijwayelekile, kudinga okuncane kwezibhobho fokusekela ukuncipiswa kwezikhathi zokusebenza ngokujwayelekile kumasebenzi amakhulu.

- Yiziphi izibonelo ezengezeka kuzo ngokudla ngokusebenzisa i-diamond polishing technology? Izibonelo zilandela i-pad ezinezindlela zokubonisa ukuthi ziyathatha kanje, izakhiwo ezifanelela kwezimali ezikwa umoya oluncedo, nezindlela zokuqina ukusetshenziswa kwezibhobho ngokusheshayo fokusebenzisa ngokuthuluka.