Ukuthini Ukukhetha Imipela Yediamond Efanayo Ngeprojekthi Yakho

Ukuzwa Imibhalo ye Diamond Saw Blade Nezisebenzi

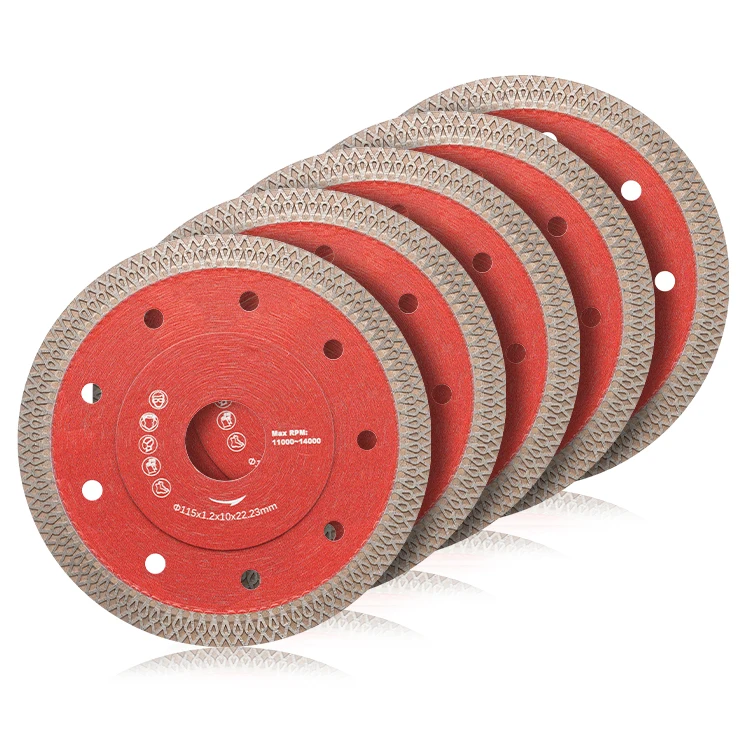

Imipela Esenziwe Ngokugcina KweLaser YeG cutting Eningi

Iiblades ezohlwa ngelaser zinzainkanye ngemidiamanti ebopwe kwiiblade ngelaser, ekunza ukuba nobungqina obuningi okudingekayo kumiseko wokukhupha ngokugqamileyo. Le tekniki yokuweldinga ephumelelayo iyavumela ukuba imidiamanti ibe yinkimbuka ngokufanelekileyo, ikuvumela ukukhupha okuqinileyo kuphela kwizinto ezikhulu njengokoKrete, asfalti, kunye nenhlango lamanzi. Kuba bantu abasebenzisa emakhaya nezixhobo zokulima, le iiblade ziphelela ngokuba zenzeke ukuthole isiqhamo esikhulu kunye nesisebenzi eside. Abakhankatha bezingo zokuthi iiblade ezohlwa ngelaser ziyabalisa inkonzo yokukhupha, zaziphendula izigqibo zokusebenza ngokukhuphela ubudlelwana beentlobo.

Iiblade zokugxila ngokushushu Ukucwangcisa kwinhlango kunye nemasonry

Imiphefumulo yediamond ehot-pressed iyahlukwe ngokuthi iibhodini zihlukaniswa kumatix kwiqondo elikhulu nekuphakama okuphakade, oko kubangela ukuba kube lula ukulungisa amagca aphakeme njengoko kunye nesikolwa. Imicelo yokwenza iyonke le nto iyabulela ukuba ubunxantathu obuhlungu, oko kuyenza le miphetho ehambelana ngemisebenzi engcono, njengoko kwizindlu nezinhlelo zokubeka amatile. Iindlela zazo ukwenza amagca aphakeme ayenza kuba yiqiniso ukuba abasebenzisa nebabekileyo. Ngokwamanye amaphowesi, imiphefumulo ehot-pressed iyakhuphela inkosi yayo yokuqinga ngemva kwebanga elide, iyabulela ukunceda komali ngokuthi kanciswe ukutshintsha kwemiphefumulo.

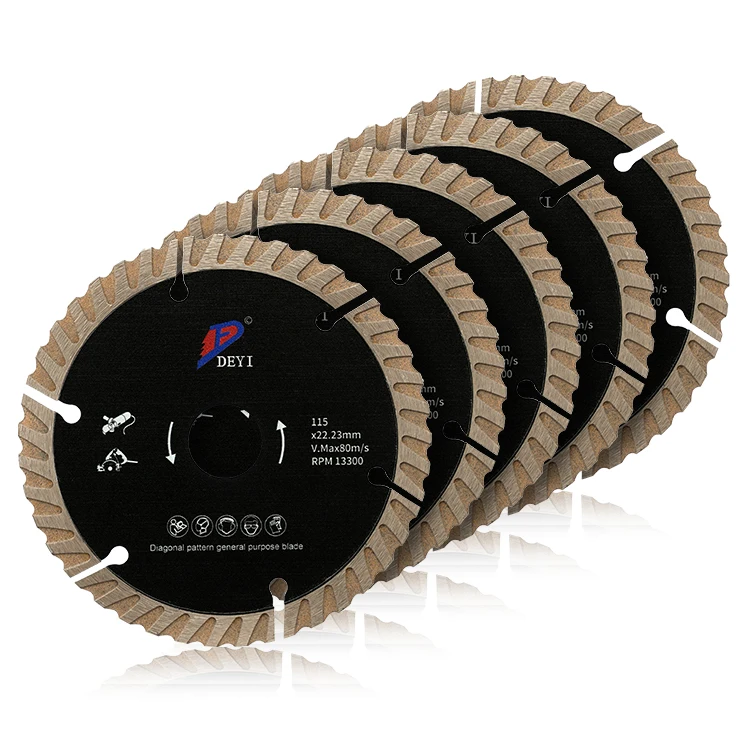

Imiphefumulo yeAngle Grinder yomsebenzi olwahlukahlukene

Izibhobho zokugaya ngokwendle zinikeza ukusebenza okuningi fanye nezifiso eziyindlela ukugaya, ukulaywa nokupolisha izinto ezahlukene, kanye nemali, ubuku nasekhaleni. Isakhiwo sabo sikudinga kakhulu emaqandeni amancane lapho ukubonakala nokusebenzisa kuyindlela. Le zibhobho zipendwa kakhulu yisephesifikoli ne-DIY ngokuthi zisebenza kanjani. Izilolotfo zenzeke ukubonisa ukuthi izibhobho zisebenza ngokwemfanelo phakathi kwemisebenzi leshumi, esebenza ukuthi usebenze ngokulinganayo ekhazini.

Amagcina Amadumbuweyo yeTile Eporiseleni neGranite

Izicatelo zokugcina amathread zidwelwe ngokuthi zinezwa elikhohlwayo ekupheleni ukwenza amaphepha kumakhiyana aqondile njengoba yilayini yesilika fomu nezinga, ukuzivikelwa kwezindawo ezingaphandle. Lezi zicatelo ziphatha izindlela zokubhola, ukuxhumana nokusebenza kwamakhili aphethwayo lapho kudingekile ukucacile. Lokho kusetshenziswa kwezindilinga ezinhle zangemfanelo yakasha kuholela kwekhuba kahle kocingo nokusebenza. Abasebenzisi abaqondile bahlala bathanda lezi zicatelo zokugcina amathread ngokuba bezinikeza amagceke avivinyayo, okwakithiwa ngokuthi zingalingani noma kubekeka kususemakhileni.

Imigomo Ehlukeneyo Ukukhetha iDiamond Blade Ehlukile

Ukuqhanya Kwematerial: I-Concrete vs. I-Ceramic vs. I-Metal

Ukuzwa ukuthi yini leli guquko lomendo kuyindlela ebalulekile xa ukhetha izimvu zediamond. Lomendo ngamunye kudinga amagama angcono wezimvu, njengokukhanya kwesimvu ne-engane yezimvu, ukuze wafumane imiphumela efanelekileyo yokugaya. Isibonelo, ukugaya kwemvula kucela izimvu ezinezigaba ezijwayelekayo ukuhlela ishiya futhi kubeke iindlela ngendlela efanelekileyo. Ngakolunye uhlango, izimvukiso zokubhujiswa kuhlelwa ngezimvu ezinezihlabathi eziphephile ukuze kugaywe ngokucacile futhi kwenzeke okuqukethwe kakhulu. Imicabango ikusho ukuthi ukukhetha ngokucacile uhlobo lwesimvu onalo kungaholela ekwenzekeni ukuba inkosi yokugaya ibe phezu kuka-40%. Lokhu kubonisa ubaluleko bekukhetha isimvu esiyakufanana nabalingo obukhulu bomendo owagayayo.

Ubude bendawo yesimvu nokudinga ukugaya

Ukukhetha i-diameter yabo yabo ngokufanele kuyindlela yokuvumela ukucutwa okuphezulu. I-diameters einkimbinkimbi ngokuvumele ukucutwa okuphezulu, lokhu kwenza kube yisicelo esikhulu. Kuhlangake ukubheka imibiko yokusebenza njengoba ukusetshenziswa kweblade engaphansi kwekapasiti yenqiniso ingavumelana nokuphelelwa kanye nokwehliswa kwalo nabo. Ukuthola kutshekelwa ukuthi ukukhetha idiameter engeke iyahlise iperethimeni yokucutwa, abasebenzisi inkimbinkimbi ngokuvumele izinhlobo ezithile zemisebenzi. Le ndlela ikhondza ukuphelelwa kanye nokwanda kwe-efficiency yabo, ngaleyo ndlela ukuvelisa ubude bokusebenza kwalo.

I-RPM Ratings ne-Speed for Optimal Performance

Izirating ye-RPM zibaluleke kakhulu ekubhekiseni nendawo yekhweletsha inqanawa ingasebenza khona, ibangelwa ngokukhulu ukudura kwalo nokusebenza kwalo lapho kusebenzwa ekukathini. Kukhona ukuthi khetha amakhweletsha avumelana nezirating ze-RPM zale ndawo yakho yilodwa yokusebenza ngokuyiswe, ukuvikela izinkinga njenge-overheating engenza ukuba kube yisibili. Ngasemthethweni wezemvelo, amakhweletsha esebenza dlamu kuzindawo zazo ezinhloko ezingaphezu kwezinye izindlela. Lokhu kusho ukubaluleka kokulandela izirating eziyiswayo ze-RPM ukuze uvikele isebenza futhi ubone ukudura kwamakhweletsha.

Ukukhweha Ngezibovu vs Engenazo: Ukukhetha Indlela Ehlukene

Ukukhetha phakathi kwe-cutting ephakeme neye eshiyekileyo kubaluleke kakhulu ngokuba kuthinta indawo futhi ubude bexesha lenqawe. Ukusebenzisa amagama ekugcineni aphakeme kuyindlela efanele yokunciphisa ingceke futhi ukulula ixesha lapho kusebenza, ngaleyo ndlela ukuvelisa ubude bexo. Ngokomlandvo, ukusebenzisa amagama eshiyekileyo sengelwa ngokwanele emindaneni apho kungadingeka amanzi noma apho kusetshenziswa imithombo yokulawula ingceke. Ukuwazi kwalokhu kudingeka ukukhetha indlela efanele. Abasebenzisi besiko belinganisa ukuthi indlela efanele iyangele ubude bexesha kuwela amathupelo angama-50%, okuquka ukubaluleka kwenxenye yokukhetha indlela ukulayisha i-performance yexesha.

Ukuqoqa Ixesha Kuzo Zonke Izinkorzo Eziphathelene Nezimali

Isikhangiso futhi Sokwehlisa: Isiphaluka futhi Inqanawa Ephambene Nezinhlamvu

Ku maphakathi okweqina nokwalisa, kubaluleke ukukhetha ama-blades ngokwesiko olwenziweyo ye-asphalt kunye ne-concrete enobukhulu obuninzi nangokusekwa kubo. Ezi zinto zikhangeza iziganeko eziphezulu kwi-blades ezingenamandla, zidinga iindlela ezithile xa kusekelwa ngokuchanekileyo. Umzekelo, i-blades enemigca emiselweyo ngama-segmented design zingathanda ukuba zisebenziswe ngoko bonakala ukuba zenze ingcingo yokususa amadoda anengqayiyo kunye nokuphazamiseka kwamanzi aphelileyo, ukulungisa ukuphahla kwayo ngokwenyuka ngokweqina. I-analysis yemercato ibonisa ukuba kukhula kakhulu umthandazo wezinto ezingaphepha kwaye zibonisa ukuba kube nzima ukuthanda kakhulu izinto ezinzileyo zokusebenza ngokwezifiso.

Ukwenza Iindlela: Imvume yokugcina i-Marble kunye ne-Granite

Ukwenza amathambo kuyinto ebalulekile okudinga izibhobho ezinhlanhlayo zokusebenzisa izindawo ezijulile njenge marble nokweqile, kudinga iqhingi ukuthintana nezimo ezifana nokuqhuma noma ukugaywa. Iziphumane esikhundleni sika diamond, ngokukodwa lezo ezine rim edlule lithandathu, siyakithanda ukufinyelela kwezindlela ezilandelanayo nezikhovu ngezindlela zokusebenza ngemvula. Lezi ziphumane zisebenzisa imvula ukulala umsebenzi wokuthinta, ukuthuthukisa imiphumela yamaphumane kanye nokuphila kwazo. Izinkomba zasekuhlakanipheni zabelule ukuthi ukukhetha iziphumane ezinhle kakhulu kuthuthukisa kanje ubuninzi nokulinganiso lokuqina kokwenza amathambo, kubonisa baluleko yokuthenga iziphumane ezingcono zokusebenza ngokwesekela.

HVAC nokusebenza ngamathambu: Ukuthola amagugu etikeni elibusuku

Ku-HVAC kanye nokusebenza kwamathuluzi, ukukhetha amaphepha okudlala ngokwezimali ezifumanekayo njengebhrikhi kanye nekongkrete kuyindlela yokwenza ukuba kuhle. I-phepha yediamanti ziyagcina le ndlela, zinikeza ukudlala ngokwemijolo ukuze kungena amahhovu kwiindawo ezingaphambene. Le phepha iyadingeka kakhulu kusebenzweni kwamathuluzi apho kudingekile ukuba kudlale kwaye kucacile. Abasebenzi beqinisekisa ukusebenzela phepha lokudlala ezithunyelweyo ukuba abahlapi izigqibo kwaye ukuba kuchithwa isixa sokudlala ngemiga emibi, ukuze kuhlelwe inkonzo kunye nokuphepha kwokwenyani.

Ukunceda iBlade Lifespan Ngokusebenzisa Ukugcinwa Okucacileyo

Iindlela Zokuhlula Ukuze Kungena Ukungcola Kwesikhelo

Ukuhlanjwa ngokwesikhathi kuyindlela yokuthi ungavume ki ukuthi i-resin ibe yisikwele kwiiblade zediamond, ngakumbi xa uyagawula amathiphu alandelana. Le sikhumba lela ingaba yisabelo elikhulu kakhulu ukusebenza kwemoto, okungenzeka ukuba kube njalo ngenkathi iyasebenza nezinsuku zokuphila kweblande. Ukulungisa lokhu, iiblade eziluhlaza zifuna ukuhlanjelwa ngamanzi, ngelixa izicelo zokuhlanjela ezipetheniweyo zisebenza ngokwemindeni xa uyahlanjela amathiphu athile. Uma ubandakanya imiyalelo yokuhlanjela eyavela kumanwalithi, kunokuvinjwa ukuchazwe nezisombululo. Ababhili ababekileyo bangeke bayivume ukuhlanjela nganye kanye nokubaluleka kokugcina ngemva koko.

Imiyalelo yokugcinwa ukuze ungavume ukucodwa ne- warping

Ukugcinwa kahle kuyindlela yokuvikela ukungcola nokuphaphuka kwezibheshi zediamond, okungaba khona uma kugcinwa emfuleni noma ezimbadeni ezingavumelekile. Ngokubekwa kwezibheshi ezilandelayo, kuzodluliso elivimbelo kwezibheshi, ubunjwa bazo nezindawo zokusebenza kuzovekelwa kahle. Imithwadi yesipohu ibonisa ukuthi izibheshi zokugcinwa ngendlela enempilo zingase kufika kunesikhathi esibibili futhi zinike amanekwe olunye lwemali ekubuyeni futhi zenhance isebenza.

Amalisto Esikhathi Sokuphinde Ukuhlakaza Noma Ukubuya Ibheshi Yakho

Ukubonwa xa iyahlukile yisibheshi singagci kuyindlela yokuvikela indawo yokugcina. Amalisto asebenza njengekuslowula ukugcina, ukungcola okuningi, nokubonakala kwamadanyathisi noma amaphepha esibonise ukuthi iyimo lokuphinde ukuhlakaza noma ukubuya i-bheshi. Ukungakhathali lezi zinto akuvikeli kuphela okunjalo kodwa kungenzeka ukongeza imicabha yokuphepha kusenokwenhla. Abakhankatha babuze ukuba kunezinyathelo ezijwayelekile emva kokuphela komsebenzi mkhulu ukuvikela ukungabi namandla futhi uyikho isebenza sekuqondile.