What Are Brazed Angle Grinder Saw Blades?

Core Construction & Material Composition

Brazed angle grinder saw blades are renowned for their robust construction using high-grade materials such as hardened steel and diamond particles. These materials contribute to both the durability and longevity of the blades, enabling them to withstand rigorous conditions. The core construction of these blades often employs a segmented design. This design is particularly advantageous as it facilitates efficient cutting and cooling during use.

Brazing Process vs. Traditional Welding Methods

The brazing process, utilized in constructing angle grinder saw blades, significantly differs from traditional welding methods. Brazing involves melting a filler metal with a lower melting point than the materials being joined, forming a robust bond without compromising the integrity of the base materials. This method is beneficial as it results in less thermal distortion compared to traditional welding, which is crucial for maintaining the blade's precision. Furthermore, brazing efficiently incorporates diamond grit onto the blade, significantly enhancing its cutting performance. Thus, the brazing process offers a competitive edge by combining strong bonding with superior cutting capabilities.

Key Advantages of Industrial-Grade Brazed Blades

Enhanced Heat Resistance for Prolonged Use

Industrial-grade brazed blades are specifically designed to resist heat buildup, significantly reducing wear and prolonging their operational lifespan. This attribute is particularly crucial for tasks that demand consistent performance over extended periods, as with concrete and stone cutting. Studies have demonstrated that blades with superior heat resistance can operate at high RPMs without deformation, thus maintaining their cutting efficiency. This resilience ensures that the blades remain effective even under strenuous conditions, offering reliability for heavy-duty applications.

Superior Bond Strength with Diamond Grit

Brazing technology creates a chemical bond between the diamond grit and the blade, which provides superior bond strength compared to traditional welding methods. This strong bond ensures that the diamonds retain their cutting abilities over prolonged periods, thereby reducing the frequency of blade replacements. This enhanced bond strength is particularly important in high-stress applications where maintaining efficiency is critical. By ensuring that the diamonds remain intact and perform optimally, these blades offer longevity and sustained cutting performance.

Compatibility with Diamond Core Drill Bits

Brazed angle grinder saw blades are crafted for seamless compatibility with a range of diamond core drill bits, enhancing their versatility in various cutting tasks. The compatibility facilitates smooth transitions between drilling and cutting applications, making these blades ideal for diverse construction projects. This adaptability proves essential when efficiently working with different materials like granite and porcelain tile. By enabling quick and effective material handling, these blades ensure task completion with precision and ease, supporting construction efficiency.

Optimal Applications in Construction & Stonework

Concrete Cutting with Diamond Drill Bit Precision

Brazed blades excel in concrete cutting, delivering precise cuts that are crucial in structural applications. The combination of brazed blades and diamond drill bits ensures smoother finishes, reducing chipping or cracking in concrete surfaces. Professionals widely recommend these tools for both residential and commercial concrete work due to their reliability and efficiency. Utilizing diamond drill bits alongside brazed blades not only enhances precision cuts but also maintains the integrity of the concrete structure during demanding tasks.

Granite/Marble Processing Techniques

For granite and marble processing, brazed blades offer the ability to cut and refine these hard materials efficiently. This efficiency is largely due to the incorporation of diamond segments, which allow for finer cuts without excessive chipping. Such precision is crucial for high-end installations where surface finish quality is paramount. Brazed blades are robust enough to handle rigorous stone-processing environments, ensuring that professionals can consistently achieve high standards of precision and quality.

Porcelain Tile Modification Strategies

When working with porcelain tiles, brazed blades provide unmatched cutting performance, significantly reducing the risk of breakage. Applying specific modification strategies with these blades ensures accurate fitments, which are essential in tiling projects where precision is key. Experts advocate the use of brazed blades for achieving clean edges and minimizing surface damage during tile modifications. These blades facilitate efficient and precise cutting, making them indispensable in both residential and commercial tiling applications.

To explore these diamond tools further, visit Beijing DEYI Diamond Products CO., Ltd. Their innovatively designed products cater to various demanding applications in construction and stonework.

DEYI's Premium Brazing-Compatible Accessories

3-Inch 7-Step Dry Polishing Pad System

DEYI's 3-inch dry polishing pad system offers a sophisticated approach to achieving high-quality finishes across various surfaces. This system features seven distinct steps designed to be compatible with brazed angle grinder saw blades, significantly enhancing performance by eliminating surface imperfections. The progressive multi-step process efficiently removes larger blemishes, simultaneously refining the material for a smooth and polished finish. This capability is particularly crucial in settings where superior finish quality is demanded, such as in high-end construction or stonework projects.

Hexagonal Wet Polishing Pad Set for Stone

DEYI's hexagonal wet polishing pad set ensures consistent stone finishing, designed to cater to the diverse needs of stone materials. These pads integrate effortlessly with brazed blades, enabling efficient wet cutting and polishing necessary for professional-grade results. Engineered for durability, this set withstands rigorous use, making it a reliable choice for professionals who perform repetitive tasks on a variety of stone surfaces. The robust nature of these pads not only ensures longevity but also enhances performance by delivering uniform finishes across different stone types.

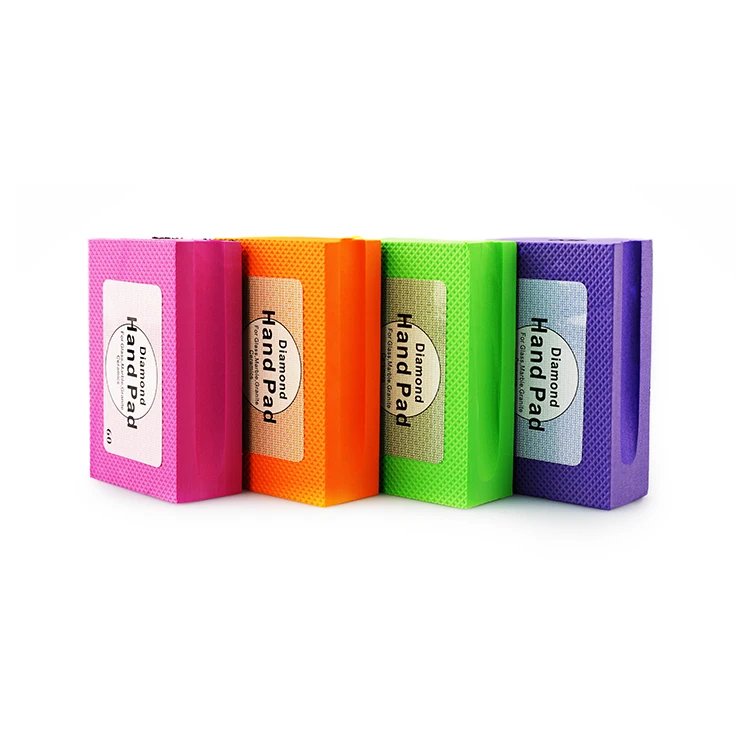

Electroplated Hand Pads for Detailed Work

Electroplated hand pads from DEYI are crafted to provide precision in detailed polishing tasks, especially useful for intricate stonework and delicate materials. These pads are compatible with a wide range of brazed blade applications, giving them remarkable versatility. They incorporate an ergonomic design that not only ensures ease of use but also reduces fatigue during extended periods of work. This ergonomic factor is particularly beneficial for artisans and craftsmen focused on high-detail tasks, allowing for greater accuracy in their projects.

Specialized Quartz Stone Polishing Solution

DEYI provides a specialized polishing solution tailored specifically for quartz stone, designed to deliver exceptional results without compromising the surface's condition. This solution is particularly effective when used in conjunction with brazed blades, making it ideal for both new installations and the refinishing of quartz countertops. By employing a targeted approach, users can ensure that the quartz maintains its inherent luster while achieving superior, smooth finishes. This makes DEYI's solution an indispensable tool in achieving high-quality, aesthetically pleasing results in quartz applications.

Maintenance Tips for Long-Lasting Performance

Proper Cooling Techniques During Operation

Maintaining the integrity of brazed angle grinder saw blades is crucial for their longevity, and proper cooling techniques play a significant role in this process. Intermittent cutting is one effective method, allowing the blade to cool down between cuts and reducing the chances of overheating. Additionally, using water or specialized coolants during operation can significantly lessen heat buildup, thereby prolonging the life of the blade. These techniques are essential, especially in high-demand applications, as they prevent premature wear and ensure consistent performance.

Diamond Saw Blade Storage Best Practices

Proper storage is key to preserving the performance and lifespan of diamond saw blades. To prevent corrosion and other types of damage, blades should be kept in a dry and stable environment. Utilizing blade cases or organizers is recommended, as they help maintain sharpness and integrity. This setup ensures that the blades are always ready for optimal performance when needed. Additionally, it's crucial to avoid stacking blades on top of each other to prevent unnecessary impact damage, which can dull the blades and lower efficiency.

When to Rotate or Replace Blades

Knowing when to rotate or replace blades is vital to maintaining cutting efficiency and preventing downtime. Monitoring wear indicators on brazed blades can inform you when a blade's performance begins to degrade. Regular inspections should be conducted after a specified number of cutting hours or whenever visible signs of wear appear. Timely rotation or replacement not only prevents costly interruptions but also enhances overall operational efficiency. By adopting these practices, users ensure that their tools perform at peak levels consistently.