Understanding Round Dry Diamond Grinding Wheels

What Makes Diamond Grinding Wheels Ideal for Marble?

Diamond grinding wheels are designed specifically for their superior hardness, which allows them to effectively cut through the dense surface of marble. This is because marble, while being a soft stone, still requires specialized tools that can provide durable support to achieve a smooth polish without damaging the surface. Their unique round profile helps in minimizing friction and heat generation, a vital feature to preserve the marble's integrity during extensive shaping and polishing processes. The cutting strength of diamonds creates a balance between speed and quality, which is essential for efficient marble finishing. Various industry research highlights that diamond wheels can accelerate grinding processes by up to 3 times compared to traditional abrasive wheels, making them a preferred choice for professionals involved in marble grinding operations.

Key Components: Grit, Bond, and Core Design

Understanding the key components—grit size, bond, and core design—is crucial for optimizing the performance of diamond grinding wheels. Grit size, for instance, plays a significant role in determining the finish quality; finer grits produce smoother finishes but demand slower grinding speeds, while coarser grits offer faster processing at the expense of a rougher surface. This detailed understanding of the grit scale is particularly important for successful marble edging. The bond is responsible for holding the diamond grit together, influencing the wheel's lifespan and its suitability for various applications. Resin bonds are ideal for softer marbles, offering a balance of flexibility and wear resistance. Moreover, the core design impacts the wheel's overall stability and vibration levels. A well-engineered core minimizes wobble, enhancing precision and safety during use, which is crucial for both quality outcomes and operator security.

Benefits of Dry Diamond Wheels for Marble Edging

Precision and Smooth Finish on Delicate Surfaces

Dry diamond wheels provide impressive precision and smooth finishes on delicate marble surfaces. Their ability to maintain a clean edge significantly reduces the need for additional polishing, which saves valuable time and labor costs. Their precise control during grinding ensures a flawless edge without risking scratches or damage to the marble, which often happens with other types of grinding wheels. Users have reported a decrease in post-edge finishing time by approximately 30%, underscoring the effectiveness of these tools in maintaining the aesthetics required for high-end marble applications.

Durability in High-Temperature Grinding

The durability of diamond wheels in high-temperature grinding processes sets them apart from traditional abrasives. Their ability to retain structural integrity at elevated temperatures makes them well-suited for the rapid grinding processes involved in marble edging. The inherent thermal conductivity of diamonds allows these wheels to be used extensively without degrading, ensuring longevity and cost-effectiveness. Studies show that diamond grinding wheels endure operational periods more than 50% longer compared to non-diamond alternatives, especially in high-temperature applications, highlighting durability as a vital advantage.

Selecting the Right Diamond Grinding Wheel

Matching Grit Size to Marble Edging Requirements

Choosing the correct grit size for diamond grinding wheels is crucial for achieving the desired results in marble edging. A coarser grit is typically used for initial shaping, while finer grits are necessary for finishing touches to ensure a smooth surface without unnecessary roughness. Furthermore, understanding the specific type of marble and its hardness is essential; softer marbles may require finer grit sizes to prevent rapid wear or damage. The relationship between grit size and surface finish quality must be carefully balanced, as an inappropriate choice could lead to an unsatisfactory surface, resulting in additional costs and labor for rectification. Professionals often emphasize that proper grit size selection can make a significant difference in maintaining the aesthetics and integrity of marble surfaces.

Bond Type Compatibility with Dry Grinding

Selecting the appropriate bond type is also a key consideration when choosing diamond grinding wheels for marble processing. Matching bond types, such as metal, resin, or ceramic, with the particular characteristics of the marble being worked on can enhance efficiency and tool lifespan. For instance, a harder bond can be advantageous when dealing with softer marble, as it helps prevent the diamonds from detaching prematurely. The right bond not only optimizes grinding performance but also enhances the durability of tools. Industry evidence suggests that selecting the appropriate bond can lead to productivity gains of up to 40%, making it a cost-effective choice in marble edging operations. This compatibility ensures that the grinding process is not only efficient but also preserves the tool integrity for longer periods, offering significant economic benefits.

Best Practices for Marble Edging Applications

Step-by-Step Guide to Edge Profiling

A systematic approach to edge profiling ensures marble surfaces attain professional-grade finishes. Firstly, select the appropriate diamond wheel, considering grit and bond suitability for the task at hand. Begin the process with rough edging to establish the desired shape. Progress to intermediate grits for structural refinement and finish with fine grits for a polished surface. During these steps, operators must maintain proper feed rates and consistent pressure to prevent inconsistencies. These techniques not only enhance the profile's quality but also reduce labor costs associated with correcting errors. Furthermore, diligent training on these procedures can significantly enhance both output and quality measurements.

Avoiding Chipping and Overheating

To effectively avoid chipping when working with marble, utilize the correct wheel speed and feed rate. Slower speeds are typically more forgiving, especially with fragile materials. Implement a cooling technique—even minimal cooling can substantially mitigate the risks of overheating. Although dry grinding wheels are commonly used, introducing some cooling can dramatically improve tool performance. Furthermore, investing in quality tools and engaging in regular maintenance prolongs tool life, ensuring minimized risks of chipping and overheating. This proactive approach not only extends the lifespan of the equipment but also guarantees consistent performance, ultimately reducing project downtime.

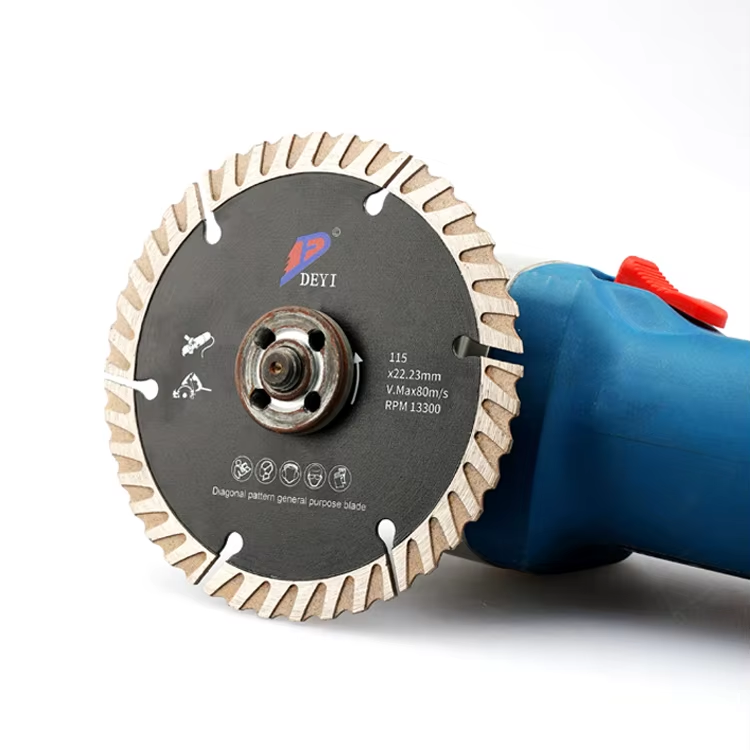

DEYI Diamond Tools: Expertise in Precision Manufacturing

20+ Years of Diamond Tool Innovation

DEYI Diamond Tools has been a leader in the diamond tool industry for more than two decades, continually pioneering innovation in product design and performance. Their commitment to pushing boundaries has allowed them to consistently exceed market expectations. Through ongoing investment in research and development, DEYI stays ahead of technological advancements, ensuring their products are both cutting-edge and responsive to evolving industry demands. This forward-thinking approach has earned them a reputation for reliability, as evidenced by numerous customer testimonials praising DEYI's diamond drill bits for glass, granite, and porcelain tile as among the most dependable in the market. The brand's deep understanding of industry challenges allows them to provide solutions that consistently meet customer needs, enhancing efficiency and precision in applications.

ISO 9001 Certification and Global Standards

DEYI Diamond Tools upholds the highest manufacturing standards, as demonstrated by their adherence to ISO 9001 certification. This certification ensures that DEYI's quality management systems are robust, fostering continuous improvement and guaranteeing customer satisfaction. It reflects their steadfast commitment to delivering reliable and high-quality products across their entire line. Being globally recognized enhances DEYI's market position, assuring clients worldwide of receiving top-tier products that meet international benchmarks. Their compliance with these standards is a testament to their dedication to quality assurance and reliability, reinforcing their status as a trusted player in the diamond tool industry.

Note: Each product mentioned, such as diamond drill bits for glass and porcelain tile, represents DEYI's expertise and commitment to excellence in precision manufacturing. To explore DEYI's detailed product offerings, visit their website and discover the tools that can enhance your projects.