Ukuthi kanjani ubukhali be-bond (ophansi, omancane, obubi) kubangelisa imfundo yesihlangothi se-diamond

Ubunzima bebandla leqobo ledlamini libaluleka kakhulu ekugcineni ubunzima besilinda esibhakathiza uma sisebenzisa. Uma siyaphawula amabandla ambalwa, kuyashiyela izinkalo ezimielo ngokushesha. Lokhu kuyakwenzela kube lula ukuthinta izinto ezikhovulayo njengekonkreti epholile ngoba kuthintela iblade ingaqhubeki yiglaze. Amadiski afaka i-medium ayenza imbili phakade phakade phakade futhi asebenze kahle kuzinto njengegranite noma umthambo. Amabandla abanzi abanamathe abaquketha izinkalo zabo kude, ngalesikhathi abasebenza kangcono xa kusekelwe kwizinto ezinzima kakhulu ezikhiqiziweyo, fakaza izinto ezijwayelekileyo njengobuchwepheshe. Abantu baseNgcamu YaseNkululeko YeTeknoloji Yokuqhiba bayeqokele isivavanyo esibonisa ukuthi uma iqobo liqobo elinamandla anezimali, libala manje ama-23 phofithi emsebenzini xa liqhiba ikhonkreti. Kungani? Ngoba izinkalo qhubeka zihamba emuva kumongo wobandla engenzeke ukuthi ziqhube ngaphansi komthombo.

Ukuthunyelana kwebhondi kuhlelo lwemithombo (concrete, tile, glass, njalo) ukuthuthukisa kakhulu okungcono

Ubunzima bomthombo buqhamuka ngokudla ukuthunyanwa kwebhondi ecolakiweyo:

| Uhlobo Lwezinto | Ubunzima Bekhanda Ecolakiweyo | Ingenzo Yophando |

|---|---|---|

| Ibhethone eliyimkisa | Esihlahleki | Khubaza ukugcwaliseka kakhulu |

| Ilepha yeporcelain | Kunzima | Kwala ukugaywa kwesizinda |

| Iglesi esibhakabhake | Umkalo | Kwala ucingo lwesibindi |

Ukusebenzisa amabhondi amanzi emthwini oshisayo kunciphisa isimo segolide, ngelisho kalula kuglasu kuthinta izilinganiso zokugaywa. Ukuthunyaniswa okulungile kwenza igolide iphinde iphinde 30–40%, njengoba kubonisiwe emathondeni alandelayo.

Indima yematriksi yesilumane ekugcineni igolide yenDlamini futhi yindlela ebhekene nesikhathi eside sokusebenza kwigolide

Amatrikes amakhali ahlelwe kuzo lezi zixhobo zidala ngokusekelwe ku-cobalt, nickel, noma izimoto zamakhali asebenza njengemitholampumulo eyambisa i-diamond grit ekugcineni inqanawa xa isebenza. Xa kujongwa izimatriki ezinezimo eziphezulu zika cobalt ezingaphezu kuka-65% yobuchwepheshe, zihlaba ngempela i-diamonds ngamaphesenti angama-18 ngaphezulu koko okudityanisiwe nesitya xa kususwa izinto ezinemvelo. Kutheni? Izifundo zibonisa ukuthi lokhu kungcono kukhokelo oluphakeme. Ubude bomkhondo obunzima kubangela ukukhula kwizindleko zokwakha ngamaphesenti angama-40%, ngakho ke kube khona ukulungana phakathi kokuthola okuqukethwe futhi okufanele kuhlala kuseto lwesivinini esikhulu.

Umbhaxekiso wendalo: Amabhondi amakhulu ayidingi ukuthi ubude bawo buhleli – kutheni ukulungana kubaluleke

Abasebenzisi abaningi bafundisa ukuthi izikhamu ezinzima kakhulu zithandabiza izixhobo ezingcono, kodwa ukuhlaziywa kwesivuno kuchaza okunye xa kusebenziwe nezimboni njenge-quartzite ne-firebrick. Isidingo sikhona ekukhuleni kokuthi izikhamu zihluka ngokushesha kangakanani ngokulinganayo no-diamonds. Uma uhamba phambi kakhulu, izixhobo ziqaqaqa futhi zibangela ukuthi izihlwebo ziphansi kakhulu. Uma udonsela kakhulu, sizothwala amadiyamini angcono ngaphambi kokuthi kuseni. Amakhampani angeziwa aqale ukuthutha lezo zikhamu ezithintekileyo ezibalulekileyo. Lezi zinhlelo ezithile zihlanganisa izindawo ezinzima nezindawo eziphelele, lokhu kubonwe ukuthi kugcwalisa ubude beblade emisebenzini lapho kuzihlweba izimbo ezahlukene. Ezinye iindawo zithengisa ukuthatha izihl replacements ngokuncane, zihlaba ixesha elingahloli futhi zilondoloze imali emuva.

Ukukhetha Uhlelo Lwe-Diamond Cutting Disc Olufanelekileyo Kwi-Material Yakho

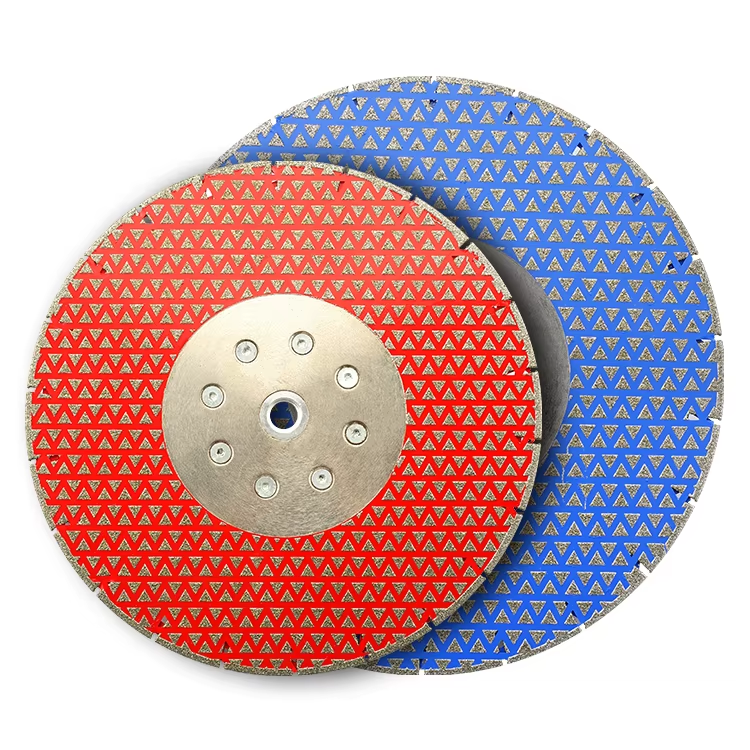

Uhlelo Lwe-Segmented vs. Continuous Rim vs. Turbo Rim Blade Nokusetshenziswa Kwazo

Ukuthola uhlelo lwesilinga esihle kuyinto eyodwa ekubaleni xa kufanele kube lula emsebenzini. Ngokomzekelo, izilinga ezihlukene zinezinkinga phakathi kwisilinga ngasinye okwenzeka ukunciphisa umthubi futhi ukususa izinkunkuma ngendlela yokuba isilinga akulahlale. Kanti, kunezilinga ezigcweleyo ezenza iziqhaza ezihlanjwayo ngezidingo, kakhulu ezinhle kakhulu kizinto ezijikelezayo njengekhaphuni nezincitha apho ubunzima kubaluleke kakhulu. Kunelabo izilinga ezinamandla amaningi anezinkinga eziqina kanye nezinqumo zokuphumula umthubi okwenzela ukuba zisebenze kahle phakathi kwezimali ezahlukene kusukela ku-granite ku-asphalt futhi nakwezincitha.

| Uhlobo lwama-blade | Kubalulekile kuma | Ingcenye Ehlukile |

|---|---|---|

| Ukuhlukaniswa | Ibhonkete, imasonri | Ukuchitha ngokushesha, ulawulo lwesibindi |

| Umngcele oqhubekayo | Ikhaphuni, izicelo, izincitha | Iziqhaza ezihlanjwayo, ukungabi kwezimali |

| Uhlelo Lwesilinga Esine-Turbo | Isteni, asifalte, ikhanda | Ukukhupha ngokushesha ngenkohlaka engaphansi yovibration |

Lapho Kufanele Usebenzise Iblade Ezinhlanjini Ukukhupha Ngokushesha I-Concrete

Amadiski akhupha ane-diamond anesegments ayasebenza kahle kakhulu xa ekhupha izinto ezibizayo njenge-concrete enezikhuthazo, izindlu zasphalt, nezinye izihlangothi ezimbi. Indlela lezi ziphala zazahlukene ngamagap phakathi kwamasegment ibangela ukuthi azidivayi kusosayensi xa ekhupha izinto ezintathu. Sekunjalo, sekwenziwe ulwazi oluthile ngozhi lwasesheshonkanyeni olubonisa amajaji okulungiselela emthonjeni abekhuthazwa ukuba aqede izisebenzi ngaphezu kuka-18% ngaphandle kokuthi bekhetha i-segmented blades kunazo zinye izinhlobo. Kodwa, xa kuyindlela enzima eningi kunesichi ezimbili, abasebenzi abaningi ngempumelelo bazokuchaza ukuthi kufanele ubale umshwelo wamanzi kule blade ngexesha lokusebenza. Oku kukunye okuncane okunciphisa ubomi bokugcina kwaye kumenza kube yinde kakhulu ngaphambi kokuthi kudinga ukubuyiselwa.

Izimphakathi ZeContinuous Rim Blades Zokwenza Umsebenzi Wengcinga Yeglasu Nemathele

Iblade zenziwe ngokuphelele zihlinza izinyalo eziphazanyayo kumagugu amatholakala ngokuthatha inhliziyo yonke kwindawo yazo engeyiyo, ihlinzela ukuthembeka kwiglasi esithandwa noma ikarpeti yesipungu. Isebenza ngempumelelo kangaka emsulwa ophezulu (3,800–5,500 RPM), okwenzela ukuthi kunciphisekile ukunyuka kwesibindi ngelishilongo lempumelelo—ngasemvelo kuneblade zenziwe ngamanye amaqubatha, angasebenze ngama-6,500–8,500 RPM.

Ukwenza Kwesitsha SeTurbo: Ukuqonda Okuphambene Nezindlela Ezilula Emfuleni Nenhliziyo

I-discs ze diamond cutting zenziwe ngendlela yokugcina isitsha zihlanganisa indlela yokuhlisa kweblade ezinezinqoba nezobuchwepheshe bezintsho eziphelele. Leli fomu elihlangene libenza:

- 25–35% yisivinini sokuhlinza kusukela kulezi zintsho eziphelele ekupheleni

-

60% yinkinga engaphezu kusukela kulezi zintsho ezingezinqoba emfuleni

Zideleke kakhulu kumsebenzi wokubopha ngokujwayelekile oqukethe izinhlayiya ezahlukeneyo, njengoko kuzimiso ezenziwa ngokushintsha ikarpeti, iphungu, nesipungu. Isicaba sakhe sezilisa esodwa sifakwa ngokuhle sinesabelo sokungena kwegunya ngaphandle kokuthinta ngokungena kwegunya.

Ukusebenzisa Izindlela Zokuhlinza Ezichanekileyo Ukwenza I-discs ZeDiamond Zibe Ngedwa

Ukukhazimba Kwe-Guquguquko Yokugcina Nokuthinta Kwalo Kwe-Diamond Cutting Disc Wear

Ukusebenza kwi-RPM enziwa ngumphathi ungcolisa ukugayayo okungahleli futhi kugcinise amagugu e-diamond. Ukukhazimba okuphakade kwenza umthwalo wapha ngaphezu kwe-300°F (149°C), kushisa kwaso isinqumo sokudonsa futhi ukuphila kwediamond. Kwi-concrete esikhuthulwayo, ukugcina izigaba phakathi kwe-4,500 ne-5,500 RPM kunciphisa izilingo zokudonsa nge-18–22% ikuselapha ukusebenzisa ngendlela engavikivi.

Ukuzivikela Ngokuqinile Okuphezulu: Indlela Ukuqinile Kuyakhathaza Ukugulwa Nezonkopho Zomugqa

Xa kuneqiniso elikhulu lokugcwalisa ngexesha lokuchasana, izinto ziqalela ukufihla kakhulu. Ukuqinisa okunye kwenza ubunzima bephanelo kubungakanani, oko kuthetha ukuba ukuchasa kungcono, ngoko ke kutheni? Abasebenzisi baya kugcina ngakumbi, oko kuphela okuyingxaki. Sisibonile njalo le nto emva kwezigaba ezininzi ezingaphandle kwemvelaphi yegolide apho izigaba ziyagcwalisa ngamathuba amathathu angaphezu kwexabiso eliqinisekileyo. Ngoku ndikunikela inyaniso yokusebenza: qhubekani ngobude bomlilo wakho. Ubuncinci bakhe nakwimo yokwahlulwa kwegazi kuya kubala indlela efika ngayo ebomlilini. Ukugcina kokuchasa akayi kukhuphuka kangangokuba, naphakade abantu bathini banezimali ezinkulu.

Ukugcina Kwe-Gunya Efanayo Ukukhokha Kwiphondo Nezenzo Ezivuthiweyo

Ukuxhentsa okungqimanga kwenza amaphethini emvukuzalo ethekeleni. Xa ucubungula izindawo ezinezinci ezininzi ezinezinci ezisixhenxe, cindezela isivinini esiqine elisekwe phakathi kwezinci ezingu-1.5–2.5 ngosondo olunye. Kukhombisa ukuthi izikhungo ezivalelwa ngaleshe lihlangothi zenzela ukuncipha kakhulu kwezinkomba zemithwalo ngama-34% (I-Journal Yezokwelapha 2023), lokhu kuyakwesekela ububi nangoba kukhona umsindle wodidi.

Isibonelo: Ukunyusa kuka-40% Kwisimo Sezigaba Ngokulungisa Indlela Esebenzayo Kubuchwepheshe Bembewu

Umphakeli wendawo yokuhlaba wanciphisa inkinga yokubuyisela i-discs zabathaka abaningi kusuka ku-11 ukuze kube ngu-7 ngalunye ulwazi lwendawo ngokusebenzisa:

- Izivinini ezilondoloziwe kwi-RPM ezingu-5,200

- Izikhungo zomthelelo nezixwayiso zomculo

- Ixesha lefileni elide ngamasekondi angu-8 phakathi kwizicubungulo

Le ndlela yabekelwa khona isimo sesimo sezindawo ezicutshwayo kusuka kuma-1,200 ukuze kube ngu-1,680 izindi zocingo ngalunye indawo.

Ukuphatha Umtamo Ngokudibanisa Okucutshwayo Noma Okucutshwayo Kungabi Ngezimali

Imiphakothi Yokucutshwa Ngemifula: Ukumela Kwamapowda, Ukusebenza Okulinganileyo, Nenkalishiyo Yobude Bezigaba Zabathaka

Ukugcina ngamanzi kuyaphucula imfikayo ngokulondoloza ubomi bokukhanya, ukuphatha izinkunkuma, nokudla okude kwezixhobo. Izinxhiba eziqukethe amanzi zilahlaza ubukhanya bezibhade ngo-60% kuphela kunemithetho engavumi manzi, ukwenza kube yimali umkhawulo wokukhanya kumazibhadi e-diamond. Ngaphezu kwalokho, amanzi ayohlaza i-silica dust esivikelwayo—lokhu kungumsebenzi ophathelene nge-OSHA—futhi ayavimba, ukuqinisekisa ukuba ukugcina kusemthwethweni.

Ukunciphisa Ukukhiqizwa Kwesikhathi Ngokusebenzisa Ukulahlaza Kamanzi Noma Imviki Yokugcina Engenamandla

Lapho kungakwenzeki ukusebenzisa amanzi ngokuvamile, imviki yokugcina engenamandla (isb., 30 sekhenji yokugcina emlandelayo 15 sekhenji yokuhlala) ingalibala imfihlelo yokulahlaza kamanzi. Iziphakamiso zibonisa ukuthi le ndlela ilahlaza ukunyakathelwa kwesikhathi ngo-40–50% emazingeni engenamandla futhi ikhuphule isimo sezibhadi e-diamond.

Izinhawu Zempilo Yokugcina Ngaphandle Kwamanzi: Ukucofa Isikhathi Sokugcina Futhi Usebenzisa Amafani Noma Amandla Okulahlaza

Lapho ukugcina ngaphandle kwamanzi kudingeka:

- Cofoza izigaba ezihlanu ku-intervals ze-90 sekhenji

- Sebenzisa amafani aphezulu noma amashayi e-coolant ukuphatha isimo

- Khetha izihlalo ze-turbo-rim zinamathuba ethuthawe ngolazeru ukuze kuvukelekele ukulahlwa kwesilulu

Ukufunda Kwezibonelo: Ukukhupha Ngamanzi Kususa Umlando WesiHlalo Ngakuya Ku-60%, Kuchaza Kabangani Umgongo Wokwephukela

Iziphanyulelo zibonisa ukuthi izihlalo ezikhethekileyo zisebenza emva kwe-250–300°F, ngempela kuye 650–800°F ezinkingeni eliphuthile. Lokhu okuchazileyo okuphelele kumlondo ngama-60% kususa umgongo wokugayaza kwegolide futhi kunciphisa isivinini sokugayazeka kwediamond, kodwa kungaba yindlela yokwandisa ubude bezinsuku zesisihlalo ngama-2.3x emaphandleni ekhokhelwayo (Abrasive Technology Journal, 2023).

Ukuphatha, Ukubheka, Nezinhlelo Zokugcina Okuhle Ekuphileni Kude

Sabela izihlalo emva kokusetshenziswa ukuze ususele amagugu akhona futhi ungavinde ikhipha

Emva kuyo yonke indlela yesetshenziso, susa igolide esithintekayo noma iglasi ephendulayo ngosikhwili se-nylon nesampula engenamandla. Amagugu adliwe avela kuhlanya okunconywa okuyakhaza ukugayazeka, kusabalazela izigaba ngakuya ku-30% ngokushesha. Kwizidingo ezikhulu, phansi isihlalo emanzini ngemizuzu engu-20 kabefore ukusikwa ukuze ungayidlaleli imatriksi yemithi.

Ukusebenzisa izindiza zokugcina ubude bwegolide ukuze kubuyiselwe inani lokugaya

Izindiza zokugcina zisusa umlonyo othuthayo okwakhiwe ngemvula yobuhlebholo, esibonisa izinkuni ezintsha ze-diamond. Abasebenzisi abagcina izigolide ngaphambi kokusetshenziswa kwezikhathi ezi-15 babuyisela inani lokugaya elingu-92% lesiqephu, kunalokho 67% kuzigolide angagcinanga (umcabango wokusebenza kwizigolide we-2023). Sebenzisa ukugcina okuncane kusengazini esingu-5–7 kuzinye zombili izihlangothi ukuze kube nesiphambano esilinganile.

Ukuhlola izigolide ngokuthatha indlela, ukulahleka okungalingani, nokuguquka kwesicathulo ngaphambi kokusetshenziswa

Yenza ukuhlola okungu-three-point ngaphambi kokusetshenziswa ngalunye:

- Hlola izinqamuzi ezimfushane emva kwe-arbor hole ngokusebenzisa ukunquma

- Faka ubude bomthelelo (susa uma iziphambano ziyaphansi kwe-1.5mm)

- Phendula igolide ku-mandrel ukuze uthole ukuthunjwa okuphansi kwe-0.8mm runout

Izigolide ezifayela kuyisebetha sithutha izivikeleke kakhulu, kakhulu kakhulu amandla okugcina neziphumo ezihluphekileyo kumsebenzisi.

Ukugcina kahle kwezincitha zokugaya ze-diamond: Evula ukumemezwa, ukuxhasana, nokuthunjwa

Kumele ukuba izilonda zilondolozwe ngokuthobela ema-rack engu-steel ezindaweni apho ubukhuni nobunzima bakhuni buqashelwa, kahle kakhulu ukugcina ubunzima bakhuni phakathi kwe-40 kuze kube ngu-60 iphesenti. Ukufaka iisilinga ze-silica gel kwiindawo zolondoloza kunceda ukuthatha umoya ofushane ofakelweyo oya kuhlala kulo ngexesha elide. Uma umntu wahlala azipakisha ngendlela ephakeme, kukho imiphumela emininzi yokuba iingcinga zeblade ziqale zithabathaba emva kweminyaka engama-8 ngokungafundwanga yiimfundo yesixhobo. Xa kuchazwa ukulondolozela izilonda ngexesha elide, kunceda ukuba uzilinde ngelayer engezantsi yeyoli. Eli layer ikhaqambisa iqonga elivikela kubunyameko apho amaqhezu e-diamond aqala ukuxhasana neebhondi zomgca apho konke kuyigunya. Iyoli ichaza njengenqamlezelo ukuze iicebo zokugaya ezikhokhelayo zilindele kwaye zisebenze kakhulu ngexesha elide.

Imibuzo Evame Ukubuzwa

Yintoni indima eyinkulu ye-bond kwi-disc yokugaya i-diamond?

Ukudibanisa kwi-disc yokugcina i-diamond kuyakha ukuthi izixhobo zokugcina zihlukunye kakuhle njengoko zisetshenziswa, kubangelwa ubungako bekhasimende phakathi kwemithombo eyahlukene.

Ubunzima be-bond bunamuphi umthelela ekusebenzeni kokusika?

Amadibaniso amahle ahlula ngokushesha i-diamonds futhi ayisemthandabeni ekugcineni imithi engcono njenge-concrete. Amadibaniso afanayo aphinde aphinde amathuba kumithi njenge-granite, ngelishwa amadibaniso amakhulu ayisemthandabeni kumazibuko amahle njenge-ceramics.

Yiziphi iziphetho ezibalulekileyo zomgcino we-segmented, continuous rim, ne-turbo rim?

Izibhedele ezigcinwe zisebenza kahle ekugcineni ngokushesha i-concrete ne-masonry, izibhedele ezingenazo i-rim zisebenza kahle ekugcineni i-glass ne-tile, kanti izibhedele ze-turbo rim zisebenza kahle ekugcineni i-stone, i-asphalt, ne-brick.

Kungani ukugcina okuphindaphindi kumelelela emathini angasebenzi ngendlela?

Ukugcina okuphindaphindi kusiza ekulawuleni ukunyuka kwesithamo nokunweleza isikhathi se-bblade ngokuthula isithambo, njengalokho okutholakala xa kugcinwa ngendlela enezinja, ngakho kususa iziqhamo ze-diamond ukungabi nomthelela wokunyukela kwesithambo.

Uhlu Lwezinto Eziqukethwe

- Ukuthi kanjani ubukhali be-bond (ophansi, omancane, obubi) kubangelisa imfundo yesihlangothi se-diamond

- Ukuthunyelana kwebhondi kuhlelo lwemithombo (concrete, tile, glass, njalo) ukuthuthukisa kakhulu okungcono

- Indima yematriksi yesilumane ekugcineni igolide yenDlamini futhi yindlela ebhekene nesikhathi eside sokusebenza kwigolide

- Umbhaxekiso wendalo: Amabhondi amakhulu ayidingi ukuthi ubude bawo buhleli – kutheni ukulungana kubaluleke

-

Ukukhetha Uhlelo Lwe-Diamond Cutting Disc Olufanelekileyo Kwi-Material Yakho

- Uhlelo Lwe-Segmented vs. Continuous Rim vs. Turbo Rim Blade Nokusetshenziswa Kwazo

- Lapho Kufanele Usebenzise Iblade Ezinhlanjini Ukukhupha Ngokushesha I-Concrete

- Izimphakathi ZeContinuous Rim Blades Zokwenza Umsebenzi Wengcinga Yeglasu Nemathele

- Ukwenza Kwesitsha SeTurbo: Ukuqonda Okuphambene Nezindlela Ezilula Emfuleni Nenhliziyo

-

Ukusebenzisa Izindlela Zokuhlinza Ezichanekileyo Ukwenza I-discs ZeDiamond Zibe Ngedwa

- Ukukhazimba Kwe-Guquguquko Yokugcina Nokuthinta Kwalo Kwe-Diamond Cutting Disc Wear

- Ukuzivikela Ngokuqinile Okuphezulu: Indlela Ukuqinile Kuyakhathaza Ukugulwa Nezonkopho Zomugqa

- Ukugcina Kwe-Gunya Efanayo Ukukhokha Kwiphondo Nezenzo Ezivuthiweyo

- Isibonelo: Ukunyusa kuka-40% Kwisimo Sezigaba Ngokulungisa Indlela Esebenzayo Kubuchwepheshe Bembewu

-

Ukuphatha Umtamo Ngokudibanisa Okucutshwayo Noma Okucutshwayo Kungabi Ngezimali

- Imiphakothi Yokucutshwa Ngemifula: Ukumela Kwamapowda, Ukusebenza Okulinganileyo, Nenkalishiyo Yobude Bezigaba Zabathaka

- Ukunciphisa Ukukhiqizwa Kwesikhathi Ngokusebenzisa Ukulahlaza Kamanzi Noma Imviki Yokugcina Engenamandla

- Izinhawu Zempilo Yokugcina Ngaphandle Kwamanzi: Ukucofa Isikhathi Sokugcina Futhi Usebenzisa Amafani Noma Amandla Okulahlaza

- Ukufunda Kwezibonelo: Ukukhupha Ngamanzi Kususa Umlando WesiHlalo Ngakuya Ku-60%, Kuchaza Kabangani Umgongo Wokwephukela

-

Ukuphatha, Ukubheka, Nezinhlelo Zokugcina Okuhle Ekuphileni Kude

- Sabela izihlalo emva kokusetshenziswa ukuze ususele amagugu akhona futhi ungavinde ikhipha

- Ukusebenzisa izindiza zokugcina ubude bwegolide ukuze kubuyiselwe inani lokugaya

- Ukuhlola izigolide ngokuthatha indlela, ukulahleka okungalingani, nokuguquka kwesicathulo ngaphambi kokusetshenziswa

- Ukugcina kahle kwezincitha zokugaya ze-diamond: Evula ukumemezwa, ukuxhasana, nokuthunjwa

- Imibuzo Evame Ukubuzwa