How to Choose the Right Diamond Saw Blades for Your Project

Understanding Diamond Saw Blade Types and Applications

Laser Welded Blades for Heavy-Duty Cutting

Laser-welded blades are engineered with diamonds bonded to the blade using a laser, ensuring enhanced durability essential for heavy-duty cutting. This advanced welding technique allows the diamonds to be robustly secured, enabling aggressive cutting through formidable materials such as concrete, asphalt, and natural stone. For those involved in construction and demolition projects, these blades are ideal due to their ability to withstand high pressures and prolonged use. Industry experts signify that laser-welded blades improve cutting efficiency, often accelerating project timelines by reducing the frequency of blade replacements.

Hot Pressed Blades for Precision in Stone and Masonry

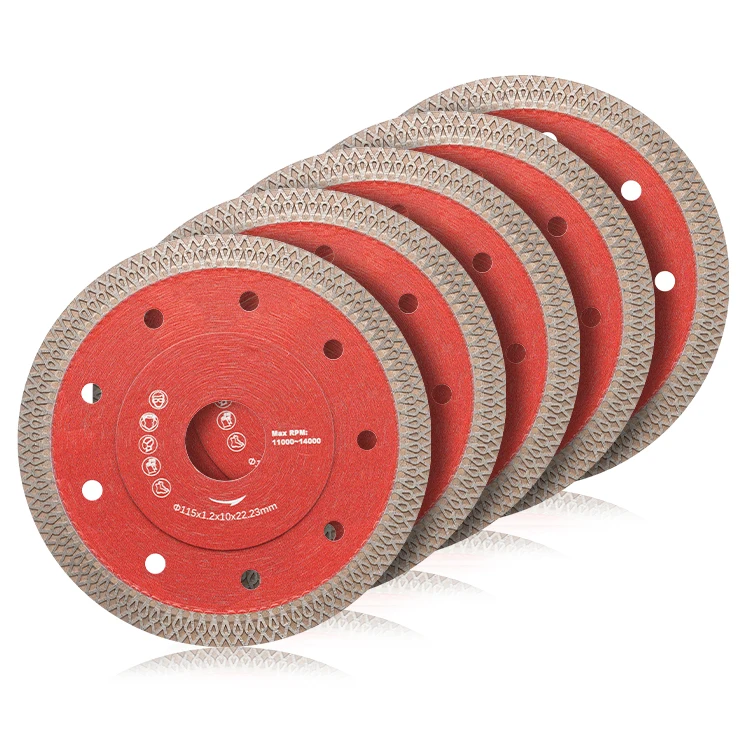

Hot-pressed diamond blades are designed by bonding diamonds to a matrix under high pressure and temperature, resulting in exceptional precision when cutting hard materials like stone and masonry. The manufacturing process ensures a sturdier bond, making these blades perfect for projects requiring intricate cuts, such as flooring and tile installations. Their ability to generate smooth finishes makes them a preferred choice for masons and fabricators. According to industry sources, hot-pressed blades maintain their cutting efficiency over extended periods, providing cost savings through reduced blade replacement frequency.

Angle Grinder Blades for Versatile Material Handling

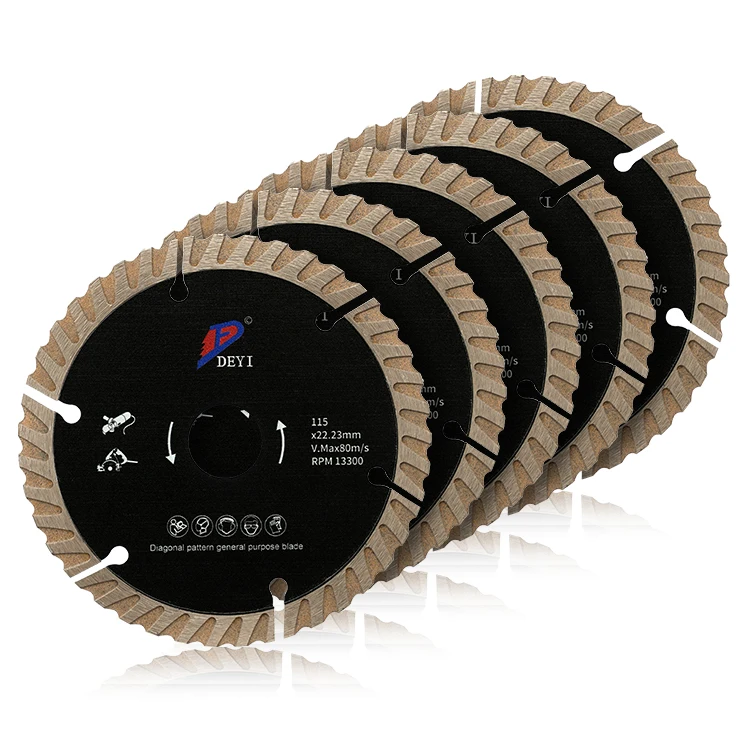

Angle grinder blades offer flexibility and are suited for cutting, grinding, and polishing a wide array of materials, including metal, wood, and masonry. Their design is particularly advantageous for smaller projects where portability and ease of use are paramount. These blades are favored in both professional and DIY applications due to their adaptability. User reviews often highlight the blades' satisfactory performance across multiple uses, substantiating their versatility in the marketplace.

Core Drill Bits for Porcelain Tile and Granite

Core drill bits are ingeniously crafted with a hollow center to facilitate precise hole creation in materials like porcelain tile and granite, avoiding damage to surrounding areas. These bits are essential in plumbing, electrical, and HVAC tasks where precision is imperative. The use of high-quality diamonds enhances tool longevity and performance. Professionals frequently commend core drill bits for delivering smooth, clean cuts, marking them as indispensable tools for working with hard surfaces.

Key Factors for Selecting the Right Diamond Blade

Material Compatibility: Concrete vs. Ceramic vs. Metal

Understanding material compatibility is a critical step when selecting diamond blades. Each material requires specific blade features, like blade hardness and diamond size, to achieve effective cutting results. For instance, cutting concrete often demands blades with a segmented design to dissipate heat and manage debris effectively. On the other hand, ceramic materials benefit from blades with a continuous rim for clean and precise cuts. Research indicates that accurately selecting the appropriate blade type can boost cutting efficiency by as much as 40%. This underscores the importance of choosing a blade that aligns with the unique characteristics of the material being cut.

Blade Diameter and Cutting Depth Requirements

Choosing the right blade diameter is essential for satisfying cutting depth requirements. Larger diameters typically enable deeper cuts, making them ideal for extensive applications. It's crucial to check equipment specifications because using a blade that surpasses the tool's capacity can risk safety and damage both the tool and the blade. Research supports that making optimal diameter selections enhances cutting performance, with professionals often recommending specific sizes for particular tasks. This approach ensures safety and maximizes the blade's efficiency, thereby prolonging its lifespan and effectiveness.

RPM Ratings and Speed for Optimal Performance

RPM ratings are pivotal in determining how fast a blade can operate, significantly influencing its longevity and effectiveness during cutting tasks. Choosing blades that match the RPM ratings of your equipment is crucial for optimal performance, preventing issues like overheating which can lead to premature wear. According to a study by machinery manufacturers, blades functioning within their prescribed RPM range tend to last 30% longer than those operated beyond their specifications. This data highlights the importance of adhering to recommended RPM ratings to ensure efficiency and extend the blade's durability.

Wet vs Dry Cutting: Choosing the Right Method

Deciding between wet and dry cutting methods is significant as it impacts both the outcome and the lifespan of the blade. Wet cutting is effective in minimizing dust and cooling the blade during operations, thus extending its life. Conversely, dry cutting is often more practical in environments where water access is limited or where dust control methods are utilized. Understanding these conditions is fundamental in selecting the right approach. Experts suggest that the proper method can increase blade lifespan by up to 50%, emphasizing the importance of method selection in optimizing blade performance.

Matching Blades to Industry-Specific Needs

Construction and Demolition: Asphalt and Reinforced Concrete

In the realms of construction and demolition, it's crucial to choose blades specifically tailored for asphalt and reinforced concrete due to their formidable density and reinforcement. These materials pose significant challenges to standard blades, necessitating specialized designs for efficient handling. For instance, blades with segmented designs are often preferred because they allow for effective debris removal and heat dissipation, preventing overheating during extensive cutting operations. A market analysis has shown a surge in demand for high-performance construction blades, indicating an increasing preference for products designed for tough applications.

Stone Fabrication: Marble and Granite Cutting Solutions

Stone fabrication is a domain that necessitates blades tailored for delicate materials like marble and granite, demanding precision to avoid issues such as chipping or cracking. Specialized diamond blades, particularly those with a continuous rim, are favored for achieving clean, polished edges with wet cutting methods. These blades utilize water to cool the cutting process, enhancing the blade's performance and lifespan. Industry studies have highlighted that selecting quality blades dramatically enhances both the efficiency and the quality of stone fabrication, underscoring the importance of investing in professional-grade granite saw blades.

HVAC and Plumbing: Drilling Through Tough Materials

In HVAC and plumbing pursuits, choosing the right drill bits for challenging materials like brick and concrete is essential for effective installations. Diamond core drill bits shine in these applications, offering precision cuts that avoid damage to surrounding structures. These bits are invaluable in plumbing work, where clean and accurate drilling is critical. Experts consistently recommend using tailored plumbing drill bits to significantly reduce the time and effort involved in drilling through tough substrates, ensuring the efficiency and safety of installations.

Maximizing Blade Lifespan Through Proper Maintenance

Cleaning Techniques to Prevent Resin Buildup

Regular cleaning is crucial to avoid resin buildup on diamond saw blades, especially when cutting sticky materials. This residue can severely impair cutting efficiency, leading to decreased performance and lifespan of the blades. To combat this, wet blades benefit from cleaning with water, while specialized cleaning agents are effective for removing stubborn residues. Following the cleaning guidelines found in user manuals can significantly enhance clarity and performance. Leading manufacturers often recommend cleaning every few cuts to ensure long-term efficiency and durability.

Storage Tips to Avoid Corrosion and Warping

Proper storage is essential to prevent corrosion and warping of diamond blades, which can occur if stored in damp or irregular conditions. By keeping blades in dry, temperature-controlled settings and using protective blade covers, their integrity and performance can be effectively maintained. Industry standards highlight that blades stored correctly can last twice as long, providing significant savings in replacement costs and enhancing usability.

Signs It’s Time to Resharpen or Replace Your Blade

Recognizing when a blade is dull is key to maintaining cutting efficiency. Indicators such as slower cutting speeds, excessive friction, and visible damage like chips or cracks signal that it's time to either resharpen or replace the blade. Ignoring these signs not only hampers performance but can increase safety risks during operations. Experts recommend conducting regular assessments post-major jobs to avoid productivity losses and ensure optimal functionality.