Diamond Tool Safety: What You Need to Know

Understanding Silica Dust Risks with Diamond Tools

Health Hazards of Inhaled Crystalline Silica

Crystalline silica poses significant health risks when inhaled, commonly leading to severe respiratory conditions. Among these are silicosis, lung cancer, and chronic obstructive pulmonary disease (COPD). Workers in sectors like construction and manufacturing, where diamond tools are frequently used, are particularly vulnerable. The Centers for Disease Control and Prevention (CDC) indicate that over 2 million U.S. workers may be exposed to respirable crystalline silica. Prolonged exposure can result in progressive lung disease, underscoring the need for stringent safety measures when using diamond tools. Implementing safety protocols and personal protective equipment is critical to mitigating these risks.

OSHA Exposure Limits and Compliance Measures

Ensuring safety when working with diamond tools entails compliance with regulations set by the Occupational Safety and Health Administration (OSHA). OSHA mandates a permissible exposure limit (PEL) of 50 micrograms of silica per cubic meter of air. Employers must adopt control measures such as effective ventilation, water suppression systems, and appropriate respiratory protection to align with these standards. Regular air quality assessments help monitor silica dust levels, ensuring both compliance and worker safety. By understanding the legal ramifications and potential penalties for non-compliance, employers are motivated to prioritize worker protection.

Wet Cutting vs. Dry Cutting Dust Control

When it comes to controlling silica dust, the choice between wet and dry cutting methods is crucial. Wet cutting utilizes water to suppress particles, significantly minimizing airborne silica levels. Studies by the National Institute for Occupational Safety and Health (NIOSH) highlight that wet cutting can reduce airborne silica by more than 90%. Although dry cutting can be more efficient in certain scenarios, it requires robust dust control solutions such as vacuum systems. Employers should carefully weigh the pros and cons of each method, considering the specific work environment and materials involved, to optimize safety and efficiency.

Selecting and Maintaining Diamond Blades Safely

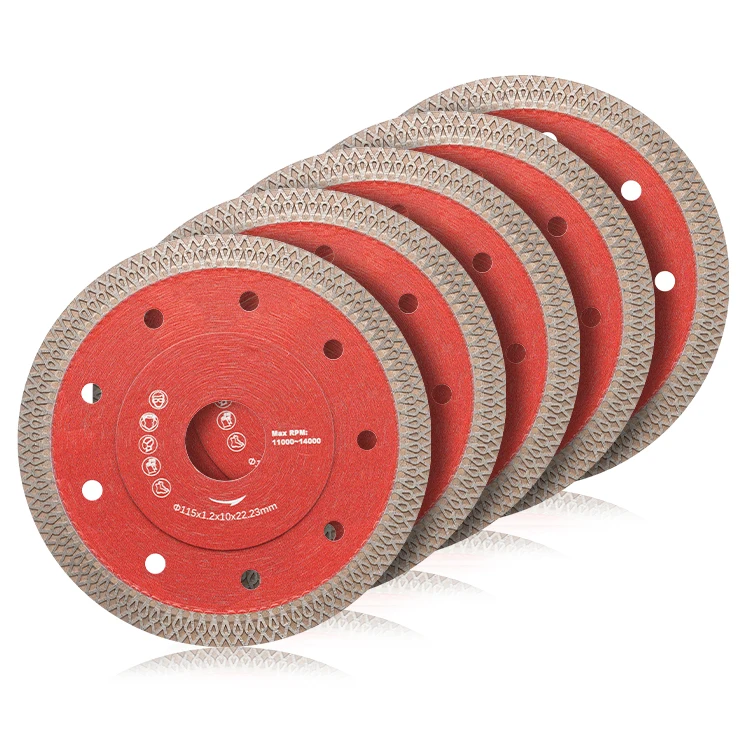

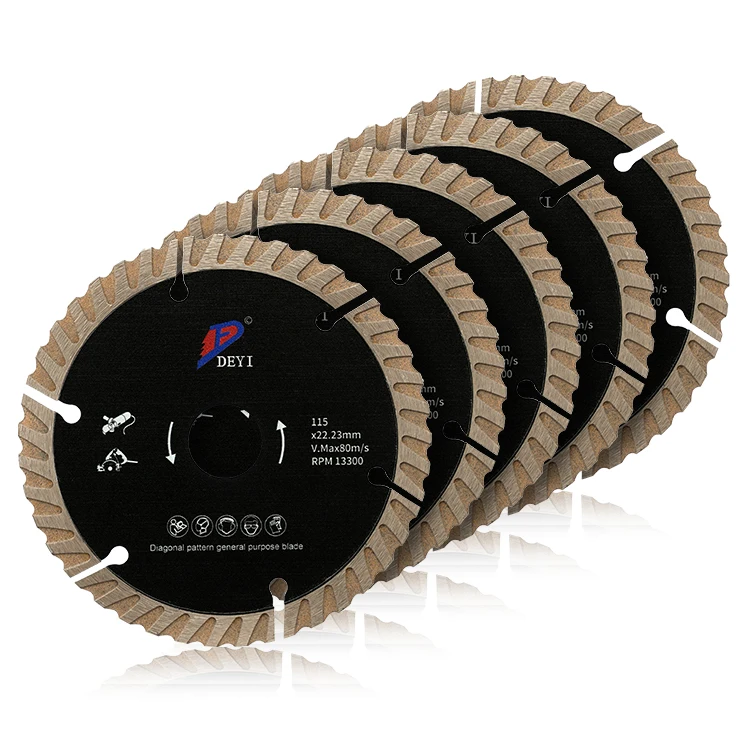

Matching Blade Specifications to Material Type

Choosing the appropriate diamond blade matched to the material at hand is paramount for cutting safety and efficiency. Each blade has specifications regarding segment height, bond type, and core thickness, which must be suited to the hardness and composition of the material—be it concrete, asphalt, or ceramic tile. When blades are mismatched to materials, it can lead to erratic cuts, damaging the tools and posing risks to safety due to instability. By adhering to manufacturer's guidelines and specifications, one can ensure the correct blade is selected, optimizing both performance and operational safety.

Maximum RPM Guidelines for Different Blades

Understanding the maximum revolutions per minute (RPM) specific to each type of diamond blade plays a crucial role in maintaining operational safety and preventing blade failure. Exceeding these RPM limits can cause overheating, binding, or catastrophic breakage of the blade, posing significant safety hazards. Technical specifications provided by manufacturers offer valuable insights into the appropriate operating speeds. Utilizing devices like tachometers to monitor the RPM during operation, especially in high-speed cutting tasks, adds an extra layer of safety.

Inspecting for Cracks and Wear Patterns

Regular inspections are vital, focusing on visible cracks, segment wear, and overall blade integrity. Conducting these inspections before and after each cutting operation helps identify early signs of deterioration, preventing performance issues and ensuring worker safety. Establishing a maintenance routine inclusive of cleaning and proper storage not only extends blade life but also guarantees consistent performance. Documenting these inspections provides a historical record, aiding in recognizing wear patterns and informed blade replacement decisions.

Proper Handling Techniques for Diamond Tools

Avoiding Kickback Through Secure Material Clamping

Securing materials properly during operations is key to preventing kickback incidents. Kickback occurs when the blade catches or binds in the material, posing a risk of serious injury to the operator. To mitigate this, employing clamps, vises, or supports ensures stability and enhances cutting accuracy. Training workers on the effective setup and secure clamping of materials is essential to reinforcing a safe work environment and avoiding accidents.

Correct Machine Setup and Blade Orientation

Ensuring accurate machine setup and blade orientation is critical to maintaining operational safety and tool longevity. Improper setup can lead to increased wear and erratic cuts, escalating safety concerns. Training operators on manufacturer guidelines for correct machine and blade setup helps ensure that proper techniques are utilized. Regular checks of blade alignment and orientation can prevent inconsistencies and minimize the risk of operational hazards.

Preventing Blade Binding in Cutting Operations

Blade binding poses significant risks, as it can cause sudden stops and potential kickback. Operators can alleviate binding by using appropriate feed rates, ensuring the correct cutting depth, and selecting the correct blade type for the material. It is important for operators to recognize signs of binding like excessive vibrations or reduced cutting speed, and respond promptly. Establishing consistent operational practices boosts both safety and productivity, ensuring smoother cutting operations.

Essential Personal Protective Equipment (PPE)

Respirator Selection for Silica Environments

Choosing the right respirator is crucial for safeguarding workers from harmful silica dust exposure. In environments where diamond tools are used, respirators must meet the standards set by the National Institute for Occupational Safety and Health (NIOSH) and be rated for the specific level of silica dust present. The effectiveness of these respirators relies heavily on a proper fit, so regular fit testing is essential to ensure an adequate seal and minimize inhalation risks. Moreover, educating workers on the correct usage and maintenance of respirators is vital—this knowledge empowers employees to reduce exposure risks and comply better with safety protocols.

Impact-resistant Eye Protection Requirements

Utilizing impact-resistant eye protection is fundamental in preventing injuries from flying particles during diamond tool operations. Protective gear, such as goggles and face shields, must comply with the ANSI Z87.1 standards to offer optimal safety in industrial environments, where diamond drill bits for glass and other materials pose significant risks. It's important for employers to champion the necessity of eye protection by conducting regular training sessions that highlight its importance and the consequences of neglecting this crucial gear. Maintaining the integrity of eye protection equipment through frequent inspections and timely replacements is essential to ensure continued safety and compliance with workplace safety standards.

Proper Glove Types for Vibration Control

Selecting gloves specifically designed for vibration control can significantly reduce the risk of developing hand-arm vibration syndrome (HAVS), a prevalent occupational health problem. Such gloves should not only dampen vibrations but also provide ergonomic benefits by ensuring a secure grip and maintaining dexterity, thus enhancing operators' control over diamond tools like diamond core drill bits and saw blades. Regular education and training on glove maintenance and inspection are vital, as worn-out gloves might fail to provide necessary protection. Employers should actively promote the use of certified vibration-reducing gloves, thereby prioritizing worker safety and enhancing comfort in high-vibration environments.

Material-Specific Safety Considerations

Using Diamond Drill Bits for Glass Safely

The correct use of diamond drill bits for glass involves several critical safety measures. Firstly, apply adequate lubrication to prevent overheating and minimize the risk of cracking the glass. Secondly, operators should employ low RPM settings to maintain precise control, thereby avoiding shattering the material. It's also imperative to wear personal safety gear, such as protective goggles, to shield against injuries from flying shards. Training in effective drilling techniques, including avoiding excessive pressure, can further enhance safety and the effective use of diamond drill bits for glass.

Granite Cutting with Diamond Core Bits

Granite cutting demands the use of specialized diamond core bits, which significantly affects both performance and safety. It's important to understand the appropriate feed rate and cooling techniques during cutting operations to prevent tool wear and accidents. Wearing the proper PPE and mastering cutting techniques are essential to reducing the risks associated with cutting such hard materials. Documenting cutting procedures can also enhance safety training and improve operational efficiency, providing comprehensive insights into safe granite cutting practices.

Porcelain Tile Blade Selection Factors

Selecting the right diamond blade for cutting porcelain tiles is critical due to the material's density and hardness. An improperly chosen blade can suffer damage and compromise safety. Opting for a continuous rim blade can minimize chipping and deliver smoother cuts, enhancing safety. Operators should be trained to recognize signs of blade fatigue and ensure timely replacement to avoid cutting failures. It's vital to maintain proper cutting speeds and refrain from applying excessive pressure, preserving blade integrity and preventing accidents during operations involving porcelain tiles.