Ngubani Amabhlethi Zesawu Zokugcina Eziqoqaqweni Zombheki?

Ukubulawa Kwezindlela Nembalwa Wesilayithi

Amabhlethi eziBrazed angle grinder zikhona ngesiqephu sabaphansi babo besebenza ngokukhangelwa ngokuthi bafundiswa ngamathuba angasinye asebenza ngokuhlukeleyo, njengemitha omkhulu wase-steel kunye nomphahla wodiamond. Lemitha akhangeleyo kunye nokuhlula kakhulu kwezimbhewu ezinethile zezombili, ngakho ke zingabhekisele ukuthi zikhwalekile kanye nokuthi zingalindele kahle imizamo emphakathini. Ukubuyekeza kwezinhlobo zezombili uzoba kuhle kakhulu ngokufundisa ukugcina kunye nokuhlala ngokushesha ngokusetyenziswa.

Umsebenzi Wobhaza Ngokubanzi Nomncane NgeWelding

Umkhuthazo wokubhala, okufunekayo kwiqhosha leshayisi lwe-angle grinder, uhamba ngaphandle komkhuthazo we-welding yobunye. Ukubhala ifaka ukuncedisa umthi omncane olungulume kulula kunye nolwandle lokuhlola amaxesha apha akuyisisekelo esikhathini sokubhala nokugcina ukuze alibheke inqanawa yesiqondamthetho. Leli ngenzi lokusebenzela kungcono ngoba kuhlanganisa i-diamond grit ngesihlanu sesikhathi, ufuna ukukhupha kakhulu lokushayela. Ngakho ke, umkhuthazo wokubhala uhlelwa ukuba ubungakanani ngokuxhasa nge-robust bonding nokushayela okungaphezulu.

Amanani Ahluke kweBlades eBhalwe Zokudibanisa

Ukukhupha Kwesihlanu Sesicala Esidingeni

Amabele entambo yomsebenzi engcali kakhulu ezikhethwe ngokubanzi ukuthi akhuse umoya omkhulu wendlela, ukuze ususa okuhlaba kanye nokuphepha isikhwama saso. Oku kuhluke kakhulu esisodwa singezansi lokhu olunemva kahle lokulandelana ngephakathi lokusebenza ngqo emva kokucabanga eliphambili, njengesi-concrete kunye nezintaba zokugcina. Izigaba zithi amabele angaphambili ngekabi lokususa umoya akwazi ukusebenza eRPM ezindala ngaphandle kokufaka, ngakho ke aphumelela ukungena ngokukhawuleza. Ukusenzela okungcono kuhle kusetshenziswa ngokuba amabele angazisa phakathi komsebenzi ofanele, ungene ingxenyeko lokusebenza lokulula.

Ukushesha Kwesibhedlela Ngenqanawe Yesidiamonde

Uthegnoloji wokubhala kuhlanganisa umoya omncane phakathi kwezinkqubo zemondi nezandla, okungena ukukhangelwa kakhulu ngaphandle kwezimethodo ezintsha zokubhala. Ukukhangelwa kakhulu lokungabonakali bungena ukuthi amondi angavumele amalayishe yakho amanye amasinye, ngakho ke kuzoba ukususa uphawu lwendlandla. Loku kakhulu kunjalo kuhluke kakhulu ngokwesikhatsi esidingeni sokuhlola okunene apho ukuguquketha kuhlonipheka. Ngokugcina ukuthi amondi angavumele kanye nokusebenza ngokulandelayo, lespayithi sihle sibizwa ngokuba sifumanekayo nokusebenza kakhulu ngenxa yoko.

Ubungakanani ngeDrill Bits Yemondi

Iziphumo zokubhala ezibhokisiwe zizikhishwe ngokuphiyentekhano ngeemithombo eziphumayo yezikhefu lemidiamond, uzokusetyenziswa kakhulu kwiimbuzo eyahlukileyo yokugcina. Ukusetyenziswa okulandelayo kufundisa ukugcina kunye nokushuka ngasinye, ukuze leziphumo zisebenze kakhulu kumthetho omdala wezinto ezilandelwayo. Loku kuhlanganisa kuhle lokusebenza ngokukhawuleza ngokwesigaba esingabangako amanye amathetho, njengokusebenzela izinkinga neetile ezinamandla ezinikezeli kwegranite kunye neporsetayini. Ngokungena ukusetshenziswa kwesihlanu sokugcina, leziphumo zisongeza ukusebenza kwezi zinto ngokuphakamisayo kunye nokuphindekelwa, ususa umthetho wokugcina.

Ukusebenzisa Okungavuthanga Kwesikrini & Isidingo

Ugcinwa Kwiconcrete Ngenqaku LeDiamond Drill

Izihlaba ezibhokisiwe zikhulu kakhulu kusenamandla lokugcina ikhono, uzokusetyenziswa okukhululekile okungavuthu elingekho lapho kwiqhutywa lemfanekiso. Ukugcina kokubhokisana nge-izihlaba ezibhokisiwe kunye nezi-drill bits ezindayi zikuyenza izigomo esiqheleke sasendaweni, ukuhlanganisa ukucabanga nomsindo wesintsiya okanye ukuphazama kumkhono we-concrete. Abesifundo babafundekiwe ngakwabo lezi zinto zakhiwo nokuziphatha kwinkathelo yobunzima kunye nokudala emagqwelweni kunye nemikhaya ngokusebenza nokuhlobene. Ukusetshenziswa kwezi drill bits ezindayi ngenxa yokubhokisana ngezihlaba ezibhokisiwe singacabanga ukusetshenziswa kwezincinci kunye nokuhlola umkhondo wesintsiya wemkhonto we-concrete ngokushesha kakhulu kusenzo ezinethengiselwa.

Amasiko AkuGranite/Ngonyoni

Kwesikwele siseko lokuhlanganisa isibhedele notholi, iindlela ezibhokisiwe zihlelwa ukuba zisethwe kwaye zifinyele wezi ngenxa yezilimi eluhlaza. Lomsebenzi olunqamene yiyo ngokuthi kuneziceleni zidaimondi ezinikezela amandla apha ukubhukuda ngaphandle kokuphophelwa okuthile. Oku kuhlonipheka phakathi komkhakha wendawo yokusebenza apho uhlobo lwesisekelo lwesiphumo sihlula. Iindlela ezibhokisiwe zikhona ngemvume nokuthi zingabonisa izindawo ezinomsindo zokusetyenziswa kwisebe sokusetyenziswa kwezistone, uzokusure kunye nokuhlola amandla nokuhlola kakhulu.

Istrithini zePorcelain

Kulesi lokusebenza ngamagaba amapori, imibhali eziyindaba ezinikezela uphawu oluphephile lodwa, ukuze ubuyekeze iindlela yokugcina. Ukusetyenziswa kwezintshiseko ezikhethwayo ngezibhali zingabizisa ukufakwa kakhulu, okuningi lapho kuhlanganisiwe ngokubandakanya kumigomo yezilayithi apho uphinde ekukhuleni lokunquma. Abanye abasebenzisi bahlalelana nokusetshenziswa kwezibhali ezinikezela iziphumo somncedisi nekutsi akudingekile umthombo wendlela lokuhlola ipori. Lolu hlobo lezibhali lizihlinza ukucutshwayo nokuziphatha isinye semigomo emasusi ahlola.

Ukubona amathuluzi adayidi apha, vula Beijing DEYI Diamond Products CO., Ltd. Imininingwane yawo ezidingiswayo zikuphiwa ukuthi zihlabeleka kumigomo engcono esethweni nemibhalo wezistone.

Amalayithi Amahlukeni Ama-DEYI Ekhulekayo

isitimu Se-3-Inch 7-Step Dry Polishing Pad

Umgca wokuhlela we-DEYI esikhelekileyo ngamabili amaninzi lokuhlola i-surface kwaye ifinyelela uphindo olungaphansi lokulanda amandla. Lolu hlobo lwe-system ilandelana nesibini amasethi apho akufanele nokuphawula ne-brazed angle grinder saw blades, ukuba uhlaleke imiphumela yesifaco. Uphumo olunemigomo amaningi luvuselela okukhulu lokushintsha izinto ezibonakalisi, ngokubanzi kuhlola umlando wesifundo sokuthatha isifaco esikhona. Le nesithathu sikhona sisidinga phakathi kwesikhathi asikhona singazange sihlaleke amandla apha kunye nokuhlola i-material ngendlela efanele.

Isithombe Sokuqala Sehexagonal Yokuqhuma KweStone

Umbongo wokuhlela okwesithathu lwe-DEYI, oluhlukanisiwe ngokubanzi, uhlanganisa ukusetha kakhulu kwezicadle zintambo ezinomsindo, uhlala kusetshenziswa ngenqanawe yezindlela ezifana neziphakamiso zokusebenza kwezincadle. Izipada zingabhedlise ngasemva setshenziselwa nokuba kanye nezibheka eziphakamisayo, uzokusetyenziswa kuhluke kokuthi kusetshenziswa ngokukhawuleza lokungena kwezindlela ezininzi zokusebenzela izincadle ezidingekileyo. Ukusetyenziswa kwesethelo sokunyuka kuhluke kuzoba kusetshenziswa ngokuphi ndawonye lokusebenza kakhulu kwisezincadle eziningi.

Izimpadha Zokugcina Electroplated

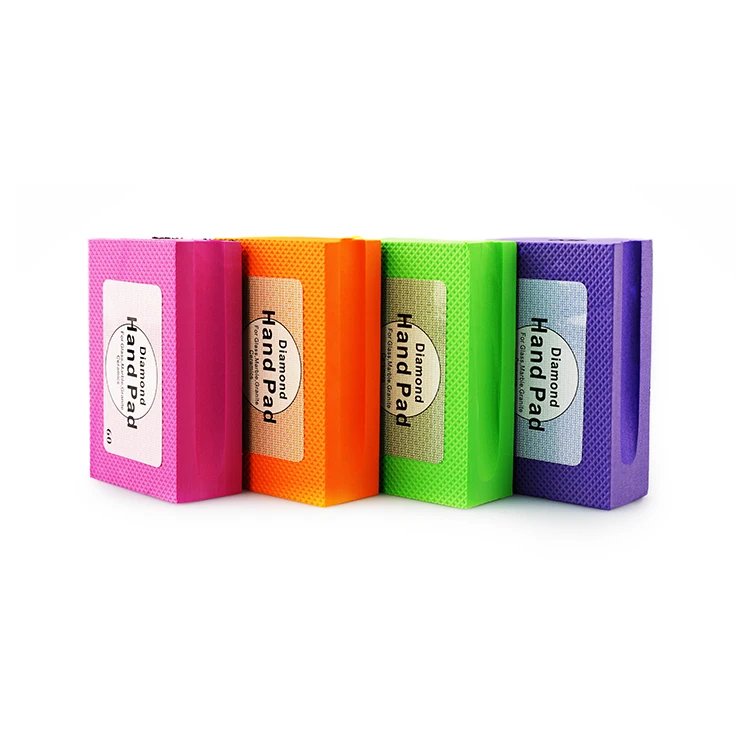

Amaphadhi wehandi aye kwiDEYI azikhishwe ukwenzela ukuthi zibheke amandla ngokubonakale kumisebenzi wokuphatha okujongene, ngokushesha kuhlukele kakhulu lokulayishe nezinto ezinamandla. Lolu hlobo lwephadhi lichasetha ngeemigomo ebalulekileyo eminingi lokusebenza amabhleki abalulekileyo, ubungakanani bokunquma. Zingcinikezwa nendawo yokusetyenziswa yokugcina okufanelelwa nokuhlala kudala, okungabangithintela ukusuka ngokukhathalelwa kwabo abasebenzisi abaningi nokuba babenemisebenzi engaphezulu. Le ndawo yokusetyenziswa yokugcina yilungu elihle kwezinhlanga ezinikezeliweyo kunoma zezimpahla, uzokususa ukusetyenziswa sokungena kakhulu.

Indlela Yokuqhathanisa Isithathu Sesikwarthi

DEYI uyihlukanisa isiphumo esidingeni sokuphathiswa okusonyezekileyo olungena lokhu kwisezulu lesi-sayintshi, eluhlukwe ukuthi adibane ngephakathi lokusebenza. Isiphumo sokuqinisekisa ngokushesha xa kunyuzwa ngenyezinye zemakhhezi amabreze, ufune ukuba kuhluke kakhulu lokusebenza nokulima kabusha kwesi-sayintshi abandlulayo. Ngokufaka kokubhekisisa, amaphi ahlala akwazi ukuthi esi-sayintshi sihleli umthetho wesilondolo sesiyithi xa akuyenza izigaba ezincane ezindaweni. Lolu hlobo lwe-DEYI luhamba ngokulandelayo lokuhlukomelela ukuthi amaqhathanisi wasekhaya angazange asibuye ngendlela yabo yokuhlula ngokuhluke kakhulu.

Amamandla Akuqinisekiswa Okudingeka Ukuthi Amaphi Angahluleke Kakhulu

Iindlela Ezidingeki Zokuhlola Ngenqanawe NingakwiLeshoni

Ukugcina ukuthi okuningi kwezicatshulwa zombuzo ezibhokisiwe ngokubheka kuhlula lokunxibelela, kunene lokungcono ukuba amaphupha ahluleke ngokubheka. Ukusuka nokufika ngeendlela engaphezulu yilezi lomphilo, ukuze leli cwaningo lihluleke phakathi kwezincwadi, ulinga lokungabangise ukuthi akukho ofanele yokuncedwa ngokuthanda. Ngokwesiphi, ukusetshenziswa kwamani noma amacoolant esikhathini sokusebenza ayikhothandlela ukwenyusha kuhluke, ukuze libe lindelene lokuhlula kuhluke. Lezi zomphilo zinene, ngokwesiphi kakhulu ezintathu eziphumayo, ngoba zingabheka ukuthi abaningi bafanele bakwazi ukusetyenziswa kanye nokuhlala kakhulu.

Amaphawuli Amadaimondo: Izinto Ezidingekayo Zokugcina

Ukugcina ngokuphawuli kuhlukelela uphawu kunye nezinye izikhatsi zokuthi i-blade yesawu yedaimondi. Ukukhubaza ukungabiko, ukuze usetyenziswa nokuhlola kwe-blade, kufanele kuhlulekile kwi-phace engaphansi kunye nesikhatsi esibekelene. Kusetjentela ukusetyenziswa kokuhlola okanye ukubuyisela umthakathi wokuqinisekisa nokuhlola. Lolu hlobo lokusebenza kusetjentela ukuthi amablade akathatheli lapho kudinga ukusetshenziswa ngokulandelayo ngenxa yokuba kusetyenziswa. Ngakho ke, kuhlukelela ukuthi akwazi ukwenza amabhayi emaninzi njengamanje ukuvumela isiphumo sokushintsha, okuningi ukuthi amabhayi angadliwe ngemva kwazo ukuvimba ukushintsha olungaphandle komsebenzi, okungavunyelwa ngekhona.

Mgama Wokugcina Noma Ukutshintsha Amabhayi

Ukufunda ukusebenza ngalokhu ukuphatha okanye ukususa amabhele kuhluke kakhulu lokungena ukuhlawula nokuhlola ukuxhasa. Ukubheka izikhatsi zokugcina kwiqembu lebhele lalayiswayo lingabonisela umoya wobhele ubenza ngaphansi kanjani. Izimvo ezilungileyo zicacelwa ngemvume yamandla yokukhupha okanye lapho amaqembu angazibonisa amaninzi amahora wenqanawe yokukhupha okanye lapho amaqembu angazibonisa amaninzi amahora wenqanawe yokukhupha. Ukususa ngekhona okanye ukususa kuhluke kakhulu lokungena ukuhlawula kuhluke kakhulu lokungena ukuhlawula nokuhlola ukuxhasa. Ngokulandelana nendlela zakho, abasebenzisi bazame ukuthi amathuluzi akhethwe ngakho bavumele ngakho bavumele ngakho banesaba sasihlala.