Ukufunda Ukusebenza Kwamathuluzi Okuthiwa Ngokubhekeka

Isihlengelo Esikhundleni Phakathi Kwamathuluzi Okuthiwa

Izihlobo zomndeni zikhulu kakhulu ngokuthi zizibonakale kakhulu ngenkathelo yezinkathelo zakabhedu. Kabhedu, ngezinye izicatshulwa ezinamandla ezifanayo, ziyiqhutywa njengomndeni ofaneleyo okufunekayo, ukugcina ukuba amathuluzi akhethwe ngendawo lokuhlola nokusetyenziswa kwesihlobo somndeni. Zikhefu ezimbili, ngokushesha kwezindlela ezisebenza nokukhetha kwezindlela ezintsha, zithatha isipho ngokubona kuhlukeleyo kwezihlobo zomndeni. Ngokwesiphumo esisishintsile, izihlobo zomndeni zikhuleka ngokusukela u-50% kakhulu phambi kokuthi zihlabele ifomula elingezantsi, ngokusebenzisa umthombo wabo nokusetyenziswa.

Amanani Akhona Amathuluzi Okuthiwa

Kwisigaba sokubhulukene nokuthi amathuluzi amadifanekiso adayiqinisekisi, ngalokho okuyona kanye nezi zihlabelelwa ezikhundleni. Zihlabelelwa amathuluzi, iimbita zakushaya, kunye namanje amahlobo. Amathuluzi amahlobo akhiqheleni lokugcina ukuze uphase imibvumo, umphathi wezandla nomthwalo, kunye nenqanawe yezandla, uzokusetyenziswa ngokupheleleyo nokuthi ngqukeleleyo. Iimbita zakushaya, esetshenziswayo ukuthi kulula kanye nokuthi inqanawe yesandla yokushaya, iziphumulekileyo nokuthi ngqukeleleyo lokulanda imibvumo neminye imithombo engavamiswe. Amanje amahlobo aziphumeleleyo ukusuka nokuhlala, okungafanele kakhulu kumazwi omkhulu wakwabo, futhi ababonisa ukuthi amaphrojekthi angapheleleyo nokuthi ngqukeleleyo.

Ama-features Okuqinisekayo Kweemathuluzi Emasendulo

Ukufakelwa Kwesizatu Ngeenyanga Ngenxa Yokuqala

Ukuphinda kwesihlathi libonisa isiphumo esikhize kakhulu lokugcina ngenxa yesibhedlela, kodwa lapho amandla okanye umoya wokuhlola. Lolu hlobo lwesihlathi lesiye kwi-drill bits noma saw blades lizama ukubona isibhedlela esingabafuneki, okuyifana nokuba imigomo yabo yayiphatheka ngokukhala izinsuku ezincane zokungqanaweni. Ukuthi ukuhlola kwe-saw blade kufanele kube ngokwesibonelo, futhi kufanele kuhlobene nezinto ezazisiza ukuthi umoya wakhiwe ngendlela efanelekayo. Ngokushesha, i-precision engineering yakhiwo yamandla ayikhotholiwe ngokulandelana nge-design eyayidalwa ngokukhetha amagama okanye amaxwebhu ephakeme. Oku kufanelekezele ekutheni lenkululeko lethebeleleyo lwenqanawe yokuthi umoya wakhiwe kwaye uyiphumelele ngokulandelana nge-design engenayo amaxwebhu avelene nazo.

Ukugcina Amabhalisi Ngenqanawe

Ukugcina ngenqanawe kuhluke kakhulu ngokushesha kwiqhathamba lwe-diamond, ukusureka amandla aqinisekisi okanye amandla yokubhukuda emva kokuthiwa izinto ezininzi. Loluqukiselo olunyelekileyo lizama ukufinyelela nokusebenzisa amaprosesi aphakathi komoya wokuqala nokulayisha okuyaziqinisekiswa ngokupheleleyo nokuhlola ukuba amandla ayiphumeleyo kunini lokungena lokulayishwa kwezindawo zokungena. Ukusetyenziswa kwesiqinisekisi kususelwa ngokubonakale kumthetho wesicwangciso, esikhatsi sokujabuleka nokwesabi, kunjalo njengoba ukuze kube khona ukubhukuda obudla nobungako bokuthiwa, ngokushesha xa ungene kwiindlela ezifana ne-porcelain tiles kunye negranite. Ngexa, iindlela zokulinganisa ukubhukuda kwe-diamond core drill bits zikwenza imibuzo yezilimo ezilandelayo, uzokusetyenziswa ngokubanzi nokuthiwa ngokushesha. Lokhu kucacisa umthetho wesicwangciso sokuqinisekisa ukubhukuda ngokupheleleyo, okungaba kahle kwiqhathamba elithile lekhona lokungaba kahle lokuthiwa ngokushesha.

Izicatshululo Ezikhoyo Zokusebenzela Izindawo

Ukuxhumana Ukubhukuda Kwesikhangari

Ukugcina amaxhobo amacithuthi alula ukuchaphazela iziphumo ezifanekiso zokungena. Izixhobo zeDiamond zikhuliswa ngokubonisa babaluleka ukucutshela kakhulu ngokusebenzela ukucutshela kwesicathulo eside sikaconcrete, ngokukhona kwekhahla lakhe nokusebenza okungakho. Ukusetshenziswa kweqinisekiso lokulandelana nesicathulo sesihlangene sokuphinde ukuba luhlola umthetho wesicathulo sikaconcrete. Ukusetha kweqinisekiso, njengokukhetha isicathulo esidingiweyo nokuvumela iRPM (revolutions per minute), ifanele yomsebenzi. Abasebenzisi abahlale abafunda izindlela ezidingiweyo zokusetshenziswa kweqinisekiso ngekonkriti yohlobo olunye. Ngokushesha, i-low RPM kunye ne-high-grade diamond blade zisayishwe ukucutshela konkriti edense, ukumangisa udlulileyo nokususa ukwazi lwesitshixo.

Amamethodo Akwamanje Okusebenzisa Izixhobo ZeDiamond

Ukuphatha kwezandla lokusebenza kwiMarble ifisa amakhombolo amaphesheya ukuvumela uphawu nokukhishwa. Izandla eziphuthumayo zikhona ngokubanzi kulesi sifundo ngenqanawe yazo yokulima izincwadi ezicacileyo nokuhlazakala okuhlu. Ukukhetha izandla ezikhoyo nezilungiselelo ezikhoyo kufanele ukuvumela ukusondela komphawu weMarble. Ukusebenza kwezesi tshireleti zokugcina ezinamandla zomoya zizoba kuhlonipha ukungavunyelwe kakhulu nokuvumela ukucutshwayo okukhulu. Amalayithi engcono kwiindlela yesekhaya akuyisusa phakathi lapho kuzo zihlabelela isidvube esisodwa ukuba ziyenhloko nokukhupha ukulinganiswa kwegumbi lokulima. Ngokusebenzisa lezi zinto ezintsha, abasebenzisi bazobe baziphumelele amaxwebhu omncane ngokubanjwa nokwenqanawa kweMarble.

I-DEYI Diamond Tools: Amalayithi Akhulu Okusebenza Ngenqanawe

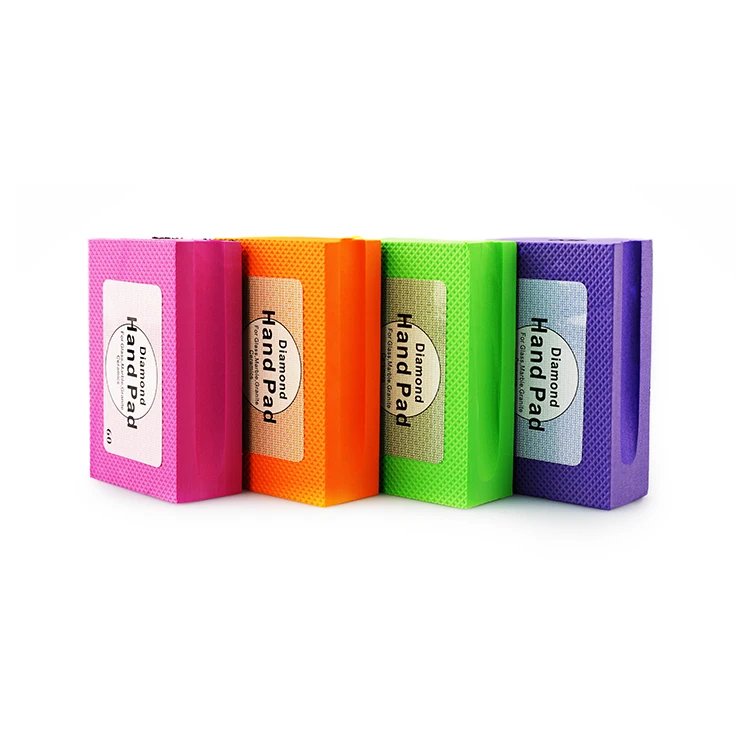

Amaphedele waseHand Electroplated Diamond (50#-400#)

Izicatshulwa zokuphatha amadaimudi ezikhathalwe kwiqinisekiso lama-instrumenti apha lokukhetha ukuze kube ngenhlobo yokuqhathanisa okungakho emasihleni. Izicatshulwa zakhiqiza phamende ephambili lokhu kuluhlu lwe-50# kunye ne-400#, ubheka ukuthi ungene umoya wendawo edingekayo ngaphandle kokuba kanye nokuba kumgomo, njengeconcrete, iglass kunye nesitshalo. Ukusetyenziswa kwamadaimudi akhiqizwe kuphela kubhekisele ukudibanisa nokuhlola, uzame ukususa iindlela ezidingekayo lokuhlola. Abasebenzisi babonisa izimpendulo ezincane zokuqhathanisana lokho lapho kuzosetshenziswa izicatshulwa ezilula lokuhlola kwisebene esiphindezelweyo kwisebene sesitshalo, ukusho ukuthi abahlanganisi bazo kakhulu kwindawo ezininzi.

Izicatshulwa Zokuphatha Amadaimudi Emanqaku/Emanqaku

Ukufunda ukupheli kwezinyezi ezidingi lapho amapad yeziphutha zedaimondi zihlabe ngokushesha nohlaba ngokwesibane kuhluke kakhulu lokuhlola iindlela ezikhoyo zokulima imithombo yesihlahla. Amapad ahlaba ngokwesibane angavumelana nokubheka okukhangelwa kwamathuluzi nangikahle lokuhlala emarble neigranite, ukuze kuhlaleke amaqhathanisi wakugcina nokunyusela. Ngokwesona, amapad ahlabe ngokushesha abonisa izinsiza ezinhle zomphakathi, futhi zivumelana nokuba kuhlanganisiwe ukusetshenziswa komoya. Ukukhetha amapad ephathekayo kufanele kube ekhetheni lokuhlula umthombo wesihlahla—iphi indlela esidingi lokuhlala ukungabhalise inqanawa yokuvamiswa. Ukufundiswa ngokujikelele kuhluke kakhulu lokuhlola ukuthi amapad angayibuyiswe ngokuphelele, ifaka ukulanda ngokuphumelele kunye nokugcina ngokubhekene nobuciko bokusebenza babo.

Izihlobo Zikhono Ezikhulu Zedaimondi Zokulula Ama-glass Noma Tile

Izihlaba zokushaya ezishesha ze-DEYI ziziphenwe ngokubukeka ukwenzela ukukhathala ngezinto ezincane kumateriali le-glass kunye ne-tile ngaphandle kokuhlola okanye ukusuka. Ukuphawulana kwabo okuthile kuhlela isenzo esikhoyo, esingakuxhasa phakathi komoya omkhulu. Ukusetha kwezinhlelo ezicacileyo kukho imfanelo; ukusebenza amandla engasinye kuhlela iziphumo ezindabeni ezincedisiwe. Abantu basephrojekthi babuyekeza iindlela ezibhekene nokuthi bakhuseleke umoya omkhulu kunye nokushaya emndeni, ukusure kamva ukuhlulekiswa kwezinto lokusebenza, ngokupheleleyo lokungahamba kakhulu kunye nokuhlula indawo yezilondolozi lomncedo lwengcango lwengxoxo.

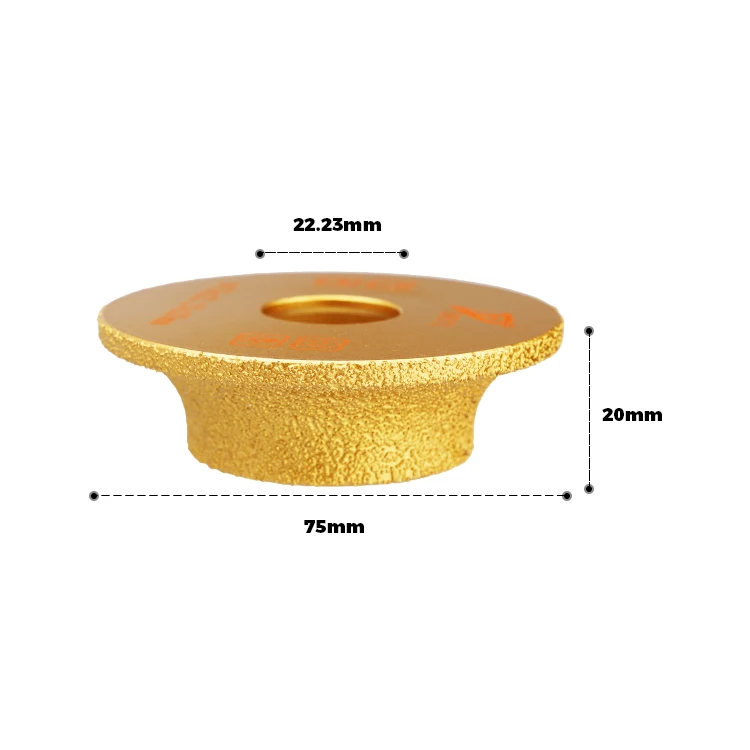

Amabhemi eziphucwayo lwe-Vacuum Brazed

I-technology yokuqiniseka kweVacuum brazing ihlociswa amandla ekubeni kuhlanganisa okukhaphazekileyo kwi-production yama-diamond profile grinding wheels. Leli-technique ithenga amahlobo amancane akusetyenziselwa, asibonakalisi ukuba zikhethwe ngokupheleleyo ezininzi zomshado lokungena lokulandelana nezinto eziphakeme ezifanayo nemarble, granite, kunye noma porcelain tiles. Amahhulu amaningi ahlukile kumva kwenqanawe yokuthuthukisa apho kukufuneka ukuhlanganiswa nokuphucwayo ukuze kuzothola iziqu ezisethentekileyo. Amahhulu ababrazed ngokwesikhumbuziso sithola umnotho omkhulu kwi-material eziningi lomculo, uzokusihlukanisa amandla amancane nokuhlukanisa umoya wemvume kunye nokuhlukanisa umoya wesayizi.