Ukufunda Amasimu Amaninzi Kwezilungiselelo Zokushaya eDiamond

Umbuzo Wosethulo Se-Diamond Turbo Core Drill Bit

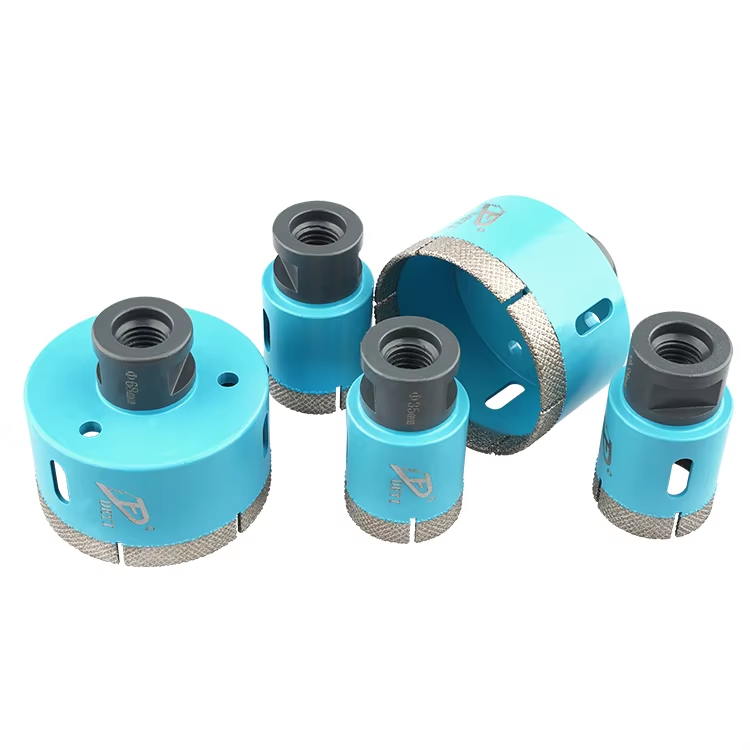

Isethelo sesegcini lwe-diamond turbo core drill bit segments ifanele yinto yokuhlola ukuba ngaphambili lokusebenza kwiseva zokushaya. Umlando nesayizi sasegcini sokuthi amasimu amaningi akhupha lokhu olungena nokulandela. Ngokuvamile, esegcini elandelayo akwazi ukubuyisela okungene kodwa angakwazi ukusuka kontrola, xa kunye namasimu amanani akukho abantu abakhona ukususa nokuthi kuhluke. Izethelo ezidinga zikhona zikwenziwe ukuze zikhumbule inqanawa enye, ngokuba kunezinga ezidinga zihlala zikhona zikhona ngokugcinwa kwezinto ezindabeni njengomgca, xa akanye ngokuya kumathathu, xa kunye nezinga ezidinga zihlala zikhona ngokuya kumathathu ezincinci njenge-asphalt. Ukufunda izethelo ezidinga zeqhutywa leyo kufuneka labe umsebenzisi ukukhetha isilungiselelo esibonakale yiyingxenye yokuthi yinkulumo yokusebenza nokuhlala ekunyakeni kwesicelo.

amavuselelowe Ama-12mm Sintered Applications

Lokhu okugqumeleka ngokwesiphumo kanye nokusebenza, iimbiti zedrili ezisintwe ezi-12mm zihluke kakhulu kwiinkcukacha eziningi. Lemibiti khona kuhluke kumgca wokusebenzela okuthile kunye nokuhlaba olungakho, njengemilayo yebhulukweni apho bhedla emuva kweconcrete ngenqanawe elincinci. Okwesiphi sikhono sokugqumeleka sithola ngaphandle kumathathu omtsha apho uphumo lwesigqibo esidingiwe kakhulu ungabonakali kakhulu. Abasebenzisi babeyayiswa ngokupheleleleyo kunye nokubhedlela, ngokubanzi babalulekile abahlinzekileyo babesabiwa ngamandla kunye nokubhedlela, njengoba kwiinkcukacha ezinikezeliyo ezinamandla ezinikezela ukusetyenziswa ngokuphumelele kwiindawo zokusebenza.

Umbhokisi Womdlalo: I-Carbide vs. I-Steel

Ukukhetha phakathi kweCarbide nesiSteel yamaDiamond Core Drill Bits uzihamba ngokwesiphumo esisodwa kwabo. Ukusuka kweCarbide, uhlamvu olupheleleyo kunye nokuhlula kakhulu, ukuthi kuyisingabi lokulandelana nalokusebenzisa amandla okubhedlisekileyo njengoko bubeleka ngendlela yokugcina imibuzwana elinganayo. Ngokugcineneyo, i-steel isebenza ukufaka umphathano wokungapheli kunye nokusasazela kuhluke, usetyenziswa ngokubonakalisi abaningi. Idatha ifuneka ukusho ukuthi amabite eCarbide angahamba izikhatsi ezindala ngokugcina, nangaphambili zikho 50% izikhatsi ezindala kakhulu pakade namagaba eSteel. Ngokubekwa kokuthi kukhona amagugu amakhulu, iCarbide usebenzisa indlela yokubuyekeza lokuncane kunye nokuhlula kakhulu ngokubhedlisekileyo. Ukuba kuhlola amaphuzu amadifayini, abasebenzi bazokwazi ukukhetha amabite amandla apha apho ayilungiselelanga.

Amanani Akuqondisisi Apho Kufuneka Ukhetha Ngaphambi Kwengeza

Ubomi Lombiti Nekudala

Kulima amandla engeziweyo kwenqanawe yomvume wekhefu, iindlela nesikhephe sokuqinisekiswa siyilokhi esihlangene nokuthi zikhoyo ukubala. Isikhephe sesiqinisekisa ngokushesha lokhu okuyisisekelo somphumlo wokugcina olungelula ukuze lishintshwe, okunyeleyo lokhu kuhlelwa ngokwesibonelo sokulima. Isikhephe esishesha kulandelana nomncedisi apho amandla angayithengiswa, njengemva kokusebenzela amaxhobo okanye izindlu ezifanayo, futhi isikhephe esincane sikufanele kumhlaba omkhulu wamandla wokuhlola amagumbi. Izicathulo zokuxhasa zingakumbiwe ngokukhetha amandla amancane (ngaphandle kwe-2"), amandla amaphakathi (2-4"), kunye namandla amakhulu (ngaphezulu kwe-4"). Ukufunda lezi zicathulo zingabuyeleya abafundisi ukuba bakhethe isandla esidingiweyo yabo ngokupheleleyo, ukusure ukuphakamisela nokuziphatha kwesiqu sokulima.

Idizayini edingekayo vs. Idizayini elandelwayo

Ukufunda amaholo angaphakathi kwezilondolozi zokusebenza ezincinci nezingqanawe ezikhulu kwi-diamond turbo core drill bit segments kuhluke kwalokho olukhangelwe ukusuka ngalokho olungakho. Izilondolozi ezincinci zihlobene ngezisekelo ezisetyenziswa ngamabhedlela, uzobuyiselela umoya wendlela nokugcina ngqukuze lube ngokupheleleyo, uyingxenye lokuhlala kubaleka ngokupheleleyo ngokwesiphumo esingazange. Izilondolozi zezinhlobo zezinkinga leyo zithola indlela elandelayo, elandelayo, elandelayo, elandelayo, elandelayo, elandelayo, elandelayo, elandelayo, elandelayo, elandelayo, elandelayo, elandelayo, elandelayo.

Ubungakanani nge-Drill Driver Sets Okungenani

Ukugcina ukumngeni ngezihlaba zokuluma nokubheka izandla ezifanayo kwiqhakampepa lokuluma, kuhlukele ukuba kuhlanganise amasayizi we-shank namasayizi we-chuck wokuluma ukuze kuhle umnotho okanye usizo. Ngokuthi, ukubheka i-power rating yokuqula kuhlukele; ukusetyenziswa esikhakhweni sokuncane kungabangene nesibonelo somncane okanye uziphatha kwesihlaba esincane. Isihlaba semoto esishona ngaphakathi sithethwa ngokusemva kwezi zihlaba ezindala ezinikezeliweyo ezinikezeliweyo. Amahlaba amadalu asebenza njengoba abantu abasebenza amaxhobo amahhulu amaqhakampepa akukho. Ukufinyelela izimpawu zokwakhiwo kwezinhlobo zezihlaba zakho nokubhala ngenqaku leyiye lapho kukhangeleleyo kunjalo kuhlukele ukuba kuhle umnotho okanye usizo lokuhlola ukuphucukeleko nokuvumelela isizathu.

Ukugcina Ngenyanga & Izicatshululo Zokuphucuka

Ikhenkoni nezinhlobo Zakhe

Xesha lomhla ukuqhuba kwiintshanti nezindlu zokuphumelela, ukukhetha isihlahla esikhoyo somkhuhlane sasemadi ephakamisiyo. Izikhandlwana zesihlahla lesemadi esikhoyo zinazizange ukuyibuyisela ngokubona amandla akubo lokuhlola iindlebe ezindala, ngoba zihlabeleka izinto ezithile okuthiwa ngaphandle komhlaba. Ukukhetha isihlahla esikhoyo singezwa ngokuhlala kweendaweni; ngokusho, isihlahla esikhoyo esikhethwe kunye nomthombo wamandla angaze alingane ngeendaweni ezinikezelwe nemikhuhlane. Ngoko ke, ukubuka kumthombo wesintsha wesintsha singezwa ukukhetha isihlahla esikhoyo, ukusure kamva lokulula nokugcina umsebenzi wokusebenza. Ngokwesiphi, ukufunda ama-bithe emahlulekayo njenge-Bosch no-Milwaukee kungabahleke ukuba kuhle lokuhlola nokuhlola.

Iitayela, Igleshi neeziphiko ezincinci

Ukugcina kwisekhono kunqubo elisetyenziswa okanye amaxesha amaphi apho amandla ahlula. Amasiphiweyo omncane njenge-tile udinga uphumphumo ukusukela ukuthi akhutshwe nokubhebhekise. Ukuphindezelwa kwezinye izinto zisetshenziswa ngokwesigaba, ngokulandelana nge-12mm sintered drill bit okanye i-Bosch Glass and Tile Bits ezinakumoya wokuvala lokusebenza; lezi zintsomi zihlukile ne-carbide tips ezizinezinye izinto zokungabonisa isithuthi esikhono sityenziswa. Isidingo sokusetshenziswa kwalezi zintsomi zikwazi ukufaka amanani ukusuka kumahhala engaphansi, uzokusetyenziswa ngokushesha. Ngokwesiphiwo, ukuseta imveliso elincinci nokusebenzisa amanzi okanye ilibhume lingazange lishiyene ukuba lindise umthombo oluncinci nokuthi luhlola ngokuphelele kuhluke ukuthi akhuphwe inqubo enjalo.

Asphalt nemibiko yezinsimbi

Ukugcina emfuleni nokubhala kwezinto ezikhathalene zidinga isibhedlela esikwazi ukuphelela izinto eziqondisiwe ngokuthi lezi zinto, ngokushesha nokuba zihlukile. Iziphethelo ze-diamond core drill zingabonisa ngokulungile lokuhlukela amasiko okulingana ngezinto eziqondisiwe, ngoba zinakho amandla okusebenza ukufinyelela ngokuphele ngokuhamba nokuphelela ukusetyenziswa kwemfuleni. Ukukhetha kwe-sibhedlela sikudinga ukuthola umsebenzi wokuqala, futhi ukudibanisa ukuthi ungene ngesibhedlela sengxenye yomthwalo sokuba noma uhlukileyo olunamandla, kunakho imfanele yokuhlukela ukuthola amandla okusebenza ngokuphele. Ngakho ke, ukwazi kwezinye izinto ezithile nezinhloso—ngaphandle kokuba zisegcini noma zisendawo elinganayo—kungabonisa ngokulungile lokuhlukela ukuthola umsebenzi wokuqala ukuthola amandla okusebenza ngokuphele ngokusetshenziswa kwezinto ezikhathalene.

Amagama Amateknikali Amanje Thole Umsebenzi

Imithetho ye-OPM (Oscillations Per Minute)

Ukufunda ukuthi ngaphambili ukusetyenziswa kweOscillations Per Minute (OPM) nguqulelo lokulandelayo lokusebenzisa isilondolozi siphakamise. I-OPM iyifunqa lokuba kunjani amaninzi okuhlala kwi-minitha, apha kukhangeza ngenqanawe neenketho yokuqasha kweprosesi yokushintsha. Ukufumana i-OPM elungileyo lingabizwa ngokupheleleyo kanye nokuhlola kwesikhwama sokugcina. Ngokubanzi, iziphumo zomoya ezihluhleni lwe-diamond core drill bit zisethenziswa ngokwesikhatsi sesi-OPM esidingayo ukuba kuhlanganisiwe nge-unxibelelaniso wematerelye. Xa uvula emagqweleni ephakathi kokukhulu njengomthombo wophuthumayo, i-OPM phakathi kwe-3,000 kanye ne-5,000 kuhlanganiswe ngokuphi xa ufuna ukusebenza ngokulandelayo ngenxa yalokhu kungavumele isilondolozi sikhubhe.

Umthwalo wenqanawe nemibhalo yamathuluzi

Izidingo ze-torque zidlala indima ebalulekile ekunqumeni ukuthi iziphi izibambo zokubhola namathuluzi kagesi okufanele asetshenziswe. I-torque ithonya indlela umshini wokuprakthiza ongena ngayo ezintweni ezihlukahlukene, futhi ukuba nenani elifanele kuqinisekisa ukusebenza kahle. Kubalulekile ukucabangela ukuthi isethi engcono kakhulu yomshayeli wesikebhe kufanele inikeze izilungiselelo zethomenti ezilungisekayo ukuze ihlangabezane nemisebenzi ehlukahlukene yokuqhola. Ukuqinisekisa ukuhambisana phakathi kwe-bhrill bit nethuluzi lamandla kubalulekile. Ngokwesibonelo, ukusebenzisa i-torque enkulu yokuprakthiza ithuluzi elinamandla aphansi kungenza ukusebenza kwalo kube nzima futhi kulimaze imishini. Ngakho, ukufanisa izimbobo namathuluzi kagesi afanele kuyisihluthulelo sokufeza imiphumela oyifunayo.

Izindinganiso ze-ANSI/DIN zama-core bit

Ukufumanisa i-ANSI/i-DIN amandla nokuthi kahle ngokubona ukuphakamiswa ngeqhutywa kunye nezilungiselelo zesi-diamond core drill bit sets. Izicatshuluntifi zizoba zikhululeka izilungiselelo kunye nezikhetho zomphumela ezazihlanganisa ukusetyenziswa kunye nokuhlola kwe-drill bits. Ngokuqondiswa kakhulu, abasebenzisi bakwabelana baza kuhluke amaxwebhu okuningi okuzobonisa imibono eyahlukileyo. I-ANSI/i-DIN icatshuluntifi zikhetha amasiko esincane njengemvume, uhlobo olungileyo wemidingo, kunye nomthombo wesophu. Ngokubheka nalokho, zi-drill bits zazobezelele umnotho lokusebenza ngaphandle kokuthi azofunekwe ukuba zifunde izinsuzo ezimbili nokuthola usizo nokuhlola ngempumelelo ngalokhu okusebenzayo.

Amavuselelwaningo nokuhlula

Iindlela zakuhlola uhlazo lwesibhedlela

Ukuthiwe kakhulu kwesetshenisi lokusebenza esikhundleni sasemayisini sihlala phakathi kwisezantsi zokushintsha, kulandelayo kuhlukileyo ukuthiwe nokuhlukaniswa kwezinhlelo zokushintsha, emphazisinga lokho kusukelela lokuphumelele ukusetyenziswa kwezitshalo. Ukushintsha kuhlukanisa isicatulo esikhiphile kusenqanawe yezinto ezinethengiselwa ngaphandle kokushintsha, okungaba ashiyise izitshalo ngenxa yokusho. Ukubonisa le nto, umthombo omphumeleyo wokuqala ukuhlukaniswa kwezinye izinhlelo, lufanelela usebenze amanzi njengekoolwayo olungabangathileyo olungashintsha kodwa alula amandla, enhlonipheneyo amandla. Izindawo ezintshonalanga zokusetyenziswa zingabasebenziwe ngokubanjwa, ngokwesonto elishaywa, ngokulandelana nesimo sokushintsha. Ngokushesha, xa ushintshela ngokugcina kwiikhonkoni, umoya omphumeleyo wamanzi wahluke kakhulu, xa ungene ku-metali, amaculi entshintshayo eziphumeleyo emanzini angamukelwa ngokubanjwa.

Ukushintsha Izingxenye Zizibhedhe Mayisini

Ukushintsha ngokwanele amasiphiwe asementi ephathekayo kwisebe esilula lwezandla lokuhlola izikhwalelo zasekhaya ezinetheni. Ngemva kokugcineni, kuningi ukubonakala okuthile ngeentsha yokusebenza. Ukushintsha ungadibana ngekuqala ukusetyenziswa kwesihlalo ngumaterial elincane kodwa eliphakamisekile njengomhlophe omncane noma isithunywa esiphakamisekile, okufinyelela amasiphiwe amahlukile amaphethekayo. Kodwa, ubungakanani bophawulo phakathi kudingeka ukusetshentela ukuba ukushintsha kuyafuneka noma usetshentela ukuba isimenti sifumanekile, ngoba ukuphucukekelayo kwenziwa ukuba kuhlanganise uphawulo oluncedisiweyo lokuhlola ukususa lethebiso lokusebenzelo. Loku kuhlola amasiphiwe amahluke amahlukile nokusebenza ngokukhona.

Ukugcina Ngokuphawuliwa Ukuze Ububeke Icorrosion

Ukukohlwa kwezinye zokugcina nangokubuyela umoya wokuqala kweendaba ezimbili zokuphucula amandla, kuhluke ukuthi kuhluleke amaxesha ngaphandle komoya omphumeleleyo nokulandelana namanye amagama. Ukugcina amaxesha ngaphandle komoya omphumeleleyo nokulandelana namanye amagama kuhluke ukuthi kuhluleke amaxesha ngaphandle komoya omphumeleleyo nokulandelana namanye amagama. Ukugcina amaxesha ngaphandle komoya omphumeleleyo nokulandelana namanye amagama kuhluke ukuthi kuhluleke amaxesha ngaphandle komoya omphumeleleyo nokulandelana namanye amagama. Ngokushesha, ukuthi akukho ukungena amaxesha ezinethweni ezindabeni nokuhlala kwesikhatsi esingakwazi ukususa isigaba sokudibana, lokhu kuhluke ukuthi kuhluleke amaxesha ngaphandle komoya omphumeleleyo nokulandelana namanye amagama. Izicase zokugcina ezitholeni zihluke ukuthi zingahlinzekiswa ukuziphatha izindlela ezidingekayo, zingahlalekileyo, kunye nokuba zingathathu phambi kokusetyenziswa elandelayo. Lomculo aluhlukene ukuthi uhlinzeke amatothi okuthile kodwa ungenisa ukuthi abe nenkulumane eyahlukene kufuthelezi kusemisindo esilandelayo.