Diamantový leštící kotouč: rychle lesklý beton

Jak fungují kotouče na broušení diamantem: Věda a technologie zrnitosti

Kotouče na broušení diamantem kombinují inženýrské brusné materiály s přesnou výrobou, aby přeměnily hrubý beton na leštěné povrchy. Tyto nástroje využívají průmyslové diamanty zabudované ve speciálních pojivech, které brousí povrchy na mikroskopické úrovni a zároveň zajišťují stálý řezný výkon.

Jak kotouče na broušení diamantem interagují s betonovými povrchy

Leštění začíná s hrubými diamantovými segmenty, které odstraňují nepravidelnosti pomocí kontrolovaného broušení. Když se kotouč otáčí rychlostí 150–500 ot./min, diamantové částice se lámou a odhalují ostré řezné hrany – tento jev se nazývá kontrolované samoostření . Tím se udržuje stálá rychlost odstraňování materiálu (0,5–2 mm/hod.) a zároveň dochází k zachování struktury kotouče.

Hydratační matrice křemičitanu vápenatého v betonu vyžaduje postupné doladění. Studie z roku 2023 zjistila, že kotouče s pryskyřičnou vazbou snižují prachu na povrchu o 50 % ve srovnání s tradičními brusivy během počátečních fází broušení.

Role zrnitosti při dosažení optimálního lesku

Postup zrnitosti sleduje přísnou posloupnost, aby odstranil viditelné škrábance:

- Hrubé (30–200 grit) : Odstraňuje nerovnosti na povrchu

- Střední (400–800 grit) : Vytváří rovnoměrné škrábance

- Jemný (1500-3000 grit) : Vytváří odrazové povrchy

- Velmi jemný (3000+ grit) : Dosahuje optické průhlednosti

Přeskočení stupně jemnosti prodlouží leštění o 35 % a zároveň hrozí trvalým matným povrchem. Podle Global Diamond Polishing Technology Report používá 83 % podlahářských firem pro komerční projekty alespoň 6 stupňů jemnosti.

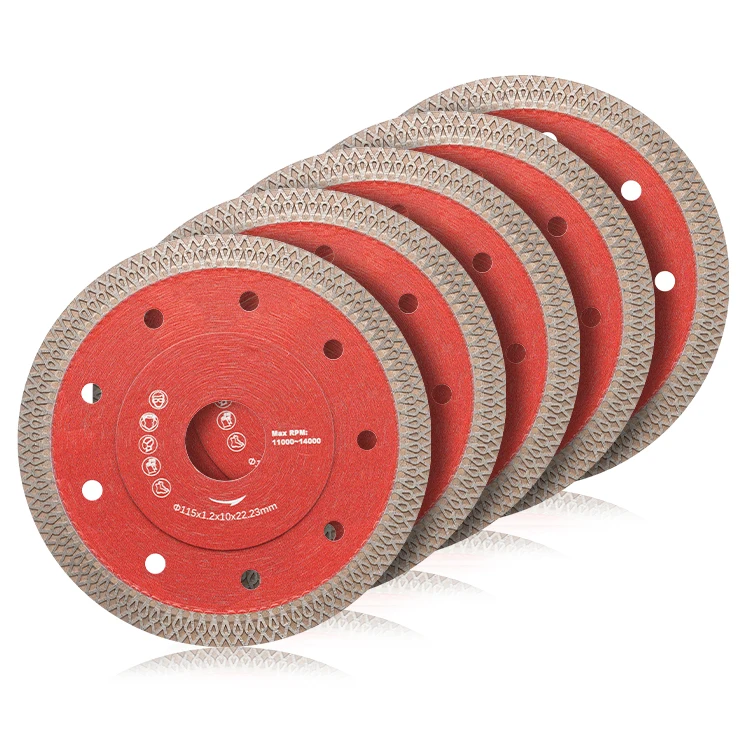

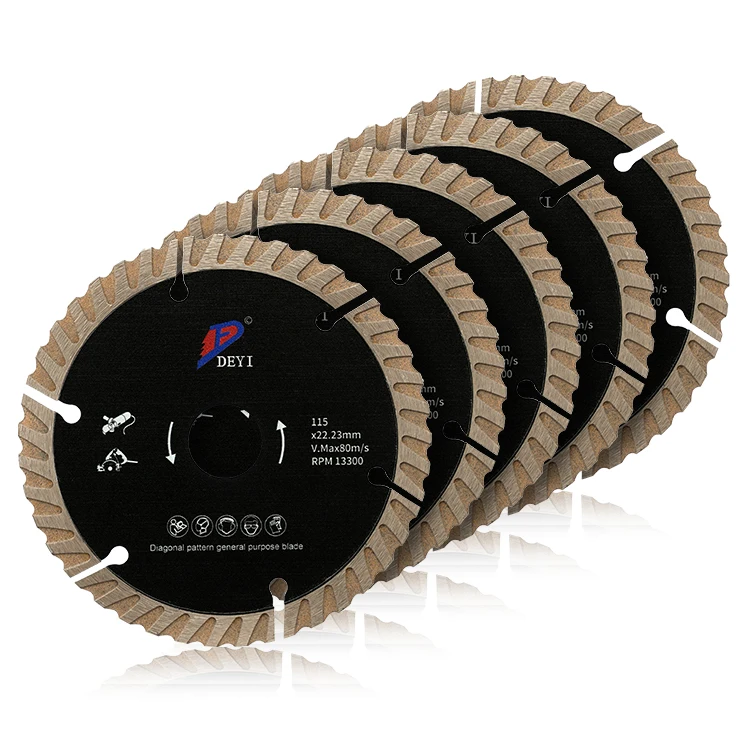

Pryskyřice vs. kov: Porozumění složení podkladu

| Charakteristika | Pryskyřicový | Kovový |

|---|---|---|

| Udržení diamantu | Postupné uvolňování | Pevná pozice |

| Ideální povrch | Dokončený beton | Hrubý beton |

| Průměrná životnost | 3 500–5 000 čtverečních stop | 7 000–10 000 čtverečních stop |

| Kvalita povrchu po dokončení | Vysoký lesk | Matný/saténový |

Kovy řízené brusné destičky dominují při odstraňování těžkých materiálů (85 % tržního podílu v průmyslových aplikacích), zatímco pryskyřové modely tvoří 72 % finálních leštících fází v dekorativních projektech.

Výhody výkonu: Rychlost, efektivita a úspora práce

Proč diamantové leštící plotny dosahují rychlejších výsledků na betonu

Diamantové leštící plotny udržují stálý řezný účinek po celé své ploše, čímž odstraňují nepravidelnosti a minimalizují tvorbu tepla. Studie o brusivkách z roku 2023 zjistila, že dosahují cílové rovinnosti o 58 % rychleji než konvenční karbidové nástroje na středně tvrdém betonu.

Úspora času a práce v komerčních projektech podlah

| Metrické | Diamantové leštění | Tradiční broušení |

|---|---|---|

| Průměrný výkon/hodina | 450–600 čtverečních stop | 300–400 čtverečních stop |

| Četnost výměny nástrojů | Každých 80–100 hodin | Každých 10–15 hodin |

| Pracovní hodiny/10 000 čtverečních stop | 18-22 | 28-35 |

U maloobchodního prostoru o rozloze 50 000 čtverečních stop může tento rozdíl ušetřit 110–130 pracovních hodin – což odpovídá částce 3 850–4 550 dolarů při průměrných odměnách v odvětví.

Porovnání dat: diamantové vs. tradiční metody leštění

-

Hrubé broušení (100 grit):

- Diamantové podklady: vyžaduje 1 průchod

- Tradiční: 2–3 průchody

-

Jemné leštění (800+ grit):

- Diamantové podklady: o 80 % méně vírových stop (ASTM D7286-13)

- Tradiční: o 42 % vyšší výskyt povrchového spálení

Dosahování vysokého lesku a odolných betonových povrchů

Projevování struktury a barevné hloubky pomocí brusných kotoučů s diamantem

Hrubé brusné kotouče (50–200 grit) odstraňují nepravidelnosti povrchu, zatímco jemnější brusiva (400–3000+) odhalují až o 40 % více dekorativního kamene ve srovnání s neleštěnými povrchy (Concrete Polishing Association). Nepoužívání nátěrů umožňuje materiálovým odstínům plně vyniknout.

Dosahování vysokého lesku bez použití nátěrů

Moderní postupy leštění diamantem dosahují odrazivosti světla 95+ díky:

- Zahušťování betonových pórů pomocí křemičitanu lithia

- Postupnému leštění 800/1500/3000 grit

- Broušení rotujícími diamantovými kotouči

Tento postup snižuje náklady na údržbu o 60 % ve srovnání s voskovými systémy (2023 Flooring Materials Report).

Trvanlivost leštěného betonu: Opotřebení a údržba v průběhu let

Správně leštěný beton odolá více než 10 let intenzivnímu provozu a zároveň si uchová 85 % původního lesku (ASTM International). Tento proces zvýší povrchovou hustotu o 35 %, čímž odolává:

- Únikům chemikálií (pH 2–12)

- Stopám od vysokozdvižných vozíků (4 000 PSI)

- Povrchovému opotřebení (7+ Mohsova stupnice)

Trend: Dekorativní beton v prodejních a zahradních prostorech

58 % luxusních prodejců vyžaduje leštěný beton s dekorativními přísadami. Mezi aktuální použití patří:

- Kovové oxidové vzory

- Odkryté říční kameny

- Geometrické konfigurace barviv

Výběr správného brusného kotouče pro leštění diamantem pro váš projekt

Volba mezi pryskyřičnými a kovovými diamantovými brusnými kotouči

Pryskyřičné kotouče (50–3 000 grit) jsou ideální pro komerční podlahy, zatímco kovové kotouče excelují při agresivním odstraňování materiálu (pod 50 grit). Analýza segmentace z roku 2024 zjistila, že pryskyřičné vazby dominují v 68 % komerčních projektů.

Strategie postupu zrnitosti pro dokonalé povrchy

- Hrubé (30–100 grit) : Vyrovnává nerovnosti

- Střední (200–400 grit) : Odstraňuje škrábance

- Jemné (800–1 500 grit) : Vytváří odlesk

- Extra jemný (3 000+ grit) : Dosahuje zrcadlového lesku

Přeskakování více než dvou úrovní jemnosti zvyšuje riziko vírových stop o 40 %.

Návod k použití: Bytová vs. průmyslová betonová podlaha

| Faktor | Bytový dům | Průmyslový |

|---|---|---|

| Lepení podkladu | Pryskyřice/hybrid | Kov/pryskyřice |

| Rozsah jemnosti | 400–3 000+ | 50–1 500 |

| Dokončete cíl | Dekorativní průhlednost | Odolnost proti skluzu |

Inovace formující budoucnost diamantové leštící technologie

Chytré podklady s indikátory opotřebení

Senzory v diamantových leštících podkladech monitorují teplotu a vzorce opotřebení, čímž snižují prostojy o 22 % (Průmyslová zpráva o brusivu 2023).

Ekologické leštění

Nové podklady snižují spotřebu vody o 50 % a produkují o 65 % méně křemičitého prachu podle Studie o udržitelné výrobě 2024.

Výhled do budoucna: Leštící systémy s podporou umělé inteligence

Systémy umělé inteligence dynamicky upravují vzorce broušení, čímž dosahují dokončení projektů o 40 % rychleji a prodlužují životnost podkladů.

Často kladené otázky

- K čemu se používají diamantové leštící plošiny? Diamantové leštící podklady se používají k přeměně hrubých betonových povrchů na leštěné povrchy tím, že je brousí a zušlechťují, aby odhalily dekorativní kamenivo a dosáhly vysokého lesku.

- Proč jsou při leštění nutné různé zrnitosti? Různé zrnitosti jsou nutné k postupnému upřesňování betonového povrchu, dosažení rovnoměrného škrábavého vzoru a odrazivého povrchu. Přeskakování zrnitostí může prodloužit dobu leštění a zvýšit riziko poškození povrchu.

- Jaký je rozdíl mezi plstěmi s pryskyřičnou a kovovou vazbou? Plstě s pryskyřičnou vazbou jsou ideální pro dokončený beton a závěrečné fáze leštění, umožňují dosáhnout vysokého lesku, zatímco plstě s kovovou vazbou jsou vhodné pro hrubý beton a intenzivní odstraňování materiálu.

- Jak diamantové leštící plstě ušetří čas a pracovní sílu? Diamantové leštící plstě zajišťují rovnoměrné odstraňování materiálu a pokryjí větší plochy rychleji než tradiční metody, vyžadují méně výměn nástrojů a snižují celkový počet pracovních hodin u rozsáhlých projektů.

- Jaké inovace se předpovídají pro budoucnost diamantové technologie leštění? Inovace zahrnují brusné destičky se ukazatelem opotřebení, ekologické konstrukce, které snižují spotřebu vody a prachu, a inteligentní systémy pro rychlejší a účinnější leštění.