Durability Advantages of Diamond Tools in Construction

Superior Material Composition for Extended Use

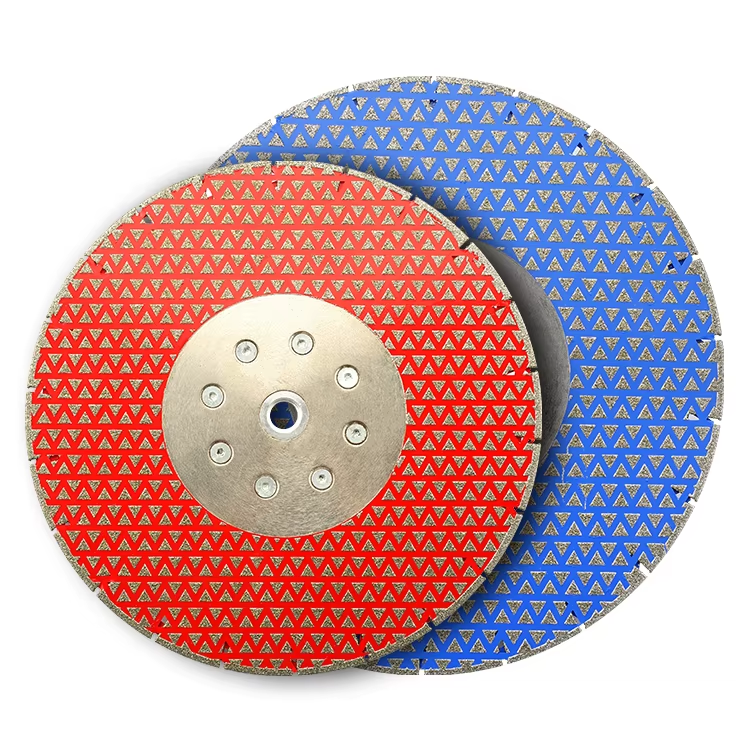

They are meant to be very hard, this is most notably thanks to the use of top-tier synthetic diamond and the best quality resins. These materials give it the necessary strength to absorb and withstand impact and abrasion while performing the roughest construction tasks. With their extremely hard design, diamonds are able to endure rough use and tear which makes them particularly useful for cutting through hard substances like granite and porcelain tiles. This means that diamond drill and core drill bits, typically used for glass and stone, have a longer service life than conventional bits. This long life means not only does the product perform consistently but replacement cycles are reduced, savaging valuable resources and waste over time.

Cost-Effectiveness Through Reduced Replacement Needs

Though with a long usage life, diamonds tools directly save a lot in the total cost of construction projects. Carpentry professionals can budget better because they will have to replace their tool less often. Diamond tools also require less maintenance, which helps them to prove more cost-effective. Offer: According to industry experts who use diamond tools, savings in tool cost can exceed 30% annually. This considerable cost saver is also also due to the tools' ability to provide uninterrupted operation and accuracy for long periods of time, and by doing so, causing professional construction companies to consider them as an excellent addition to their business – one that can help them boost their bottom line.

Enhanced Efficiency with Precision Cutting Technology

High-Speed Performance in Concrete and Asphalt Work

The diamond cutting tool has represented a leap forward in construction site efficiency by providing high speed cutting. They have excellent cutting power, cutting even concrete and asphalt, and their work time is dramatically shorter. One really appealing factor about them is how they could improve productivity – there are a lot of people who say that the speed achieved by using diamond cutting tools as high as 50% for some projects. This kind of speed is crucial for high-speed construction jobs where time is of the essence, and deadlines need to be adhered to. Progress in diamond technology has enabled these instruments to provide accurate and rapid cuts, so that they now constitute an essential tool in modern industrial activities like construction.

Optimized Workflow Through Faster Project Completion

When to Use Diamond Tools in Construction, Why, and How Using diamond tools immediately improves construction processes. The number of passes needed to cut is decreased with these tools, thus increasing productivity. Rapid project completion results in contractors completing more projects, which translates to increased profitability and more business. The research supports that companies working with diamond tools have increased project capacity and creates better customer satisfaction through more efficient processes. Diamond tools ease the workflow in the construction industry by minimizing the labour time and increasing the precision required for the construction of any project, the smoother the operation goes, the greater the productivity and efficacy in the operation of the project.

Multi-Material Versatility of Diamond Tools

Specialized Applications: Granite, Porcelain, and Stone

These Diamond tools are perfect for special cuts and doing delicate tile work with materials such as granite, porcelain and natural stone. They are precise and can't be beat for minimizing waste and getting the maximum out of high value materials that need fine craftsmanship. For instance, whether you need to work with fragile porcelain tiles or tough granite slabs, diamond tools make precision working possible, with minimal risk of spoilage of the real qualities of the material itself. This flexibility enables diamond tools to go with the flow, and be perfect for use with even the most demanding paving jobs within the stone industry.

Adaptable Solutions for Drilling and Grinding Tasks

Diamond bits drill bits and diamond core drills are both very effective at drilling a variety of different materials including stone and granite. This flexibility broadens their field of application, which is indispensable in construction and renovation works. Their wide scope of use makes them suitable for use with materials ranging from concrete to natural stone, always providing optimum performance and a good result. Experts in the industry prefer diamond tools due to their versatility to cater to various needs, emphasizing on the better performance and durability that these types of products offer. This is what makes diamond tools a must-have in the arsenal of both the contractor and the tradesman who are at the top of their game.

Noise Reduction and Environmental Benefits

Quieter Operation Compared to Traditional Equipment

The application of diamond tools in construction and industrial environments is a game changer in terms of a noise. This means the working environment is more comfortable which is very important in reducing fatigue and the risk of accidents than with high-noise traditional tools. The result is not only that there is less noise for the laborers who have to work for hours on the site, but also the residents in surrounding areas have their peace restored. At the same time, quieter work not only makes sites safer by minimizing accidents that can be caused by loud distractions, but it eases stress on construction crews as it appears to be better for workers’ mental health, according to research.

Dust Suppression Techniques for Healthier Job Sites

If that’s not enough, diamond tools also outperform every other tool in the area reducing of dust — that means a healthier job site. Many of these units also feature integrated dust suppression, for a cleaner, healthier working environment. This low-dust output of material is essential to the health of workers and avoids threatening respiratory problems, plus it meets tough safety regulations regarding air-borne particle matter. Furthermore, those organizations that invest in dust suppressive technology are able to improve air quality, as well save costs by eliminating laborious post-project clean up and project time which can improve on-site efficiency and keep their workforce happy.

Technological Innovations Driving Future Adoption

Cordless Diamond Tool Systems for Mobility

Cordless solutions for construction Cordless diamond tool systems have arrived to change the construction process in terms of mobility and ease of use on the jobsite. The removal of power cords means that workers will be free to move anywhere at will, in very challenging or remote locations. User comments say the portability and convenience of these systems bring efficiency and user satisfaction to the fore. “ Cordless technology advancements could lead to improved productivity, especially in situations where access to power is limited, hence the demand; Australian market for cordless diamond tools is increasing,” explained the FMI analyst.

Integration With BIM and Automated Construction Processes

The combination of advanced diamond instrument with BIM systems and computerized construction methods has transformed industrial procedure by making it easier for total project management. This linkage permits accurate design and operation to minimize the chance of mistakes. Industry insiders expect the automation trend to continue to grow leveraging sophisticated software tools in the next few years. Thanks to the potentialities opened up by BIM construction professionals are now able to optimize resources more efficiently thus resulting in better results and the dissemination of the use of diamond tools in automated processes.