Why Diamond Tools Excel in Tile Cutting

Superior Hardness & Abrasion Resistance

Diamond tools are unparalleled in the world of cutting hard materials such as porcelain and granite due to the natural hardness of diamonds. Their extreme hardness allows them to cut through these tough substrates with more ease than other tools available. Furthermore, diamond tools possess abrasion resistance that ensures a longer lifespan and less frequent tool changes during projects.

Precision Engineering for Clean Edges

The precision engineering of diamond tools empowers them to make intricate cuts with minimal chipping, which is crucial for projects that require flawless finishes. Diamond blades are designed to deliver smoother finishes, enhancing the aesthetic quality of the work. Expert opinions have stressed that achieving cleaner cuts minimizes waste and maximizes efficiency, as fewer adjustments or corrections are needed during projects. This precision is particularly valued when working on high-end tile installations where clean and elegant edges are paramount.

Heat Management Capabilities

Diamond tools excel in heat management during cutting operations, thanks to their superior thermal conductivity. The effective dissipation of heat reduces the risk of blade warping and degradation, which is often encountered with other types of blades under intense cutting conditions. Research highlights that controlling heat can extend the lifespan of diamond tools by up to 25%. This capability ensures not only longevity but also consistent performance, allowing workers to maintain uninterrupted focus on precision and efficiency throughout their projects.

Types of Diamond Tile Cutting Tools

Diamond Segmented Blades for Porcelain

Diamond segmented blades are specially crafted for aggressive cuts in dense porcelain tiles. They stand out for their ability to facilitate quick debris removal during cutting operations, thereby improving cut speed and overall efficiency. Unlike solid blades, segmented blades are designed to reduce chipping, making them ideal for preserving the integrity of intricate porcelain designs. This makes them a favored choice when working on ornamental or detailed tiling projects where precision is crucial.

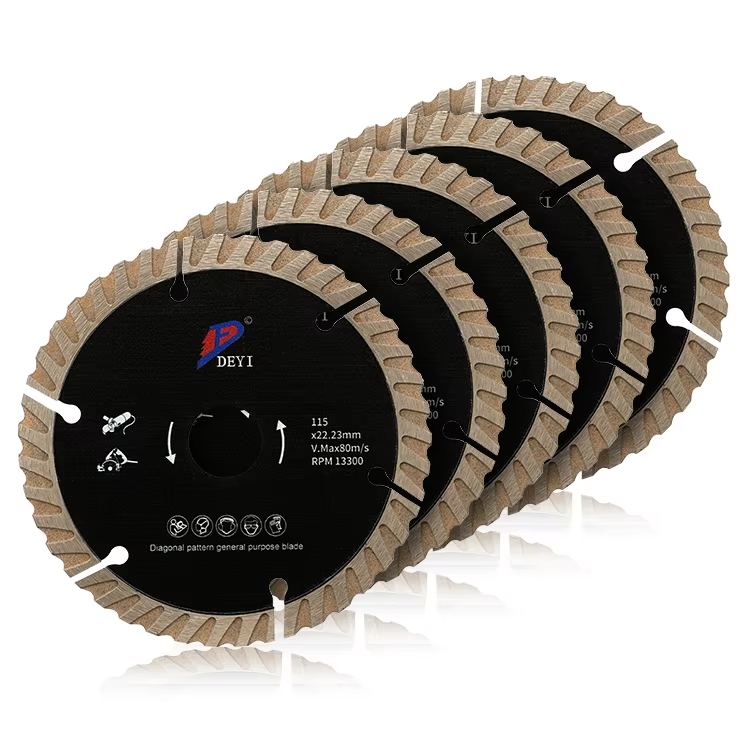

Turbo Rim Blades for Granite & Stone

Turbo rim blades, known for their continuous rim design, ensure smooth and consistent cutting through tough materials like granite and stone. These blades are engineered for high-speed operations, allowing for faster cutting without compromising the quality of the finish. Their unique design further aids in dust reduction, which is particularly beneficial in maintaining a cleaner work environment. For professionals dealing with heavy-duty stonework, these blades are indispensable due to their balance of speed and cleanliness.

Diamond Core Drill Bits for Concrete

For drilling precise holes in concrete, especially for plumbing and electrical installations, diamond core drill bits are a necessity. These bits have a hollow design that facilitates efficient removal of material, reducing waste and enhancing precision. Statistically, core drill bits tend to outlast traditional drilling methods, with records showing a considerable extension in tool life—a key advantage in large-scale construction projects. This durability, paired with the ability to drill clean, precise holes, makes them an essential tool for heavy-duty construction tasks.

Electroplated Blades for Intricate Work

Electroplated blades are renowned for their thin cutting profile, which is perfect for intricate and delicate tile work, such as art pieces or irregular shapes. They offer remarkable versatility for smaller jobs where precision is paramount, providing the finesse needed to achieve detailed installations. Experts often recommend these blades for projects that require a high degree of detail and accuracy, ensuring that even the most complex tile patterns can be realized with ease.

Optimizing Efficiency in Tile Cutting

Wet vs. Dry Cutting Applications

Choosing between wet and dry cutting methods can significantly impact efficiency in tile cutting. Wet cutting is often preferred for materials that produce a lot of dust and heat, as water helps to keep both the material and blade cool, thereby ensuring better visibility and reducing the risk of blade wear. This method is particularly effective for cutting challenging materials like porcelain, which generates significant dust. On the other hand, dry cutting offers greater convenience, especially in situations where using water is not practical. However, it's essential to note that dry cutting may not achieve the same level of precision and can be less effective for cutting extremely hard tiles. In fact, studies indicate that wet cutting methods can reduce blade wear by up to 40% compared to dry cutting techniques. It is crucial to weigh these factors against each other to determine the best cutting approach for your specific project.

Blade RPM & Feed Rate Balance

Finding the right balance between blade rotations per minute (RPM) and feed rate is crucial for optimizing tile cutting efficiency and minimizing tool wear and tear. Operating a blade at too high an RPM or feeding too quickly can result in poor cuts. This means carefully considering the type of material being cut and adjusting the RPM accordingly. For example, a lower RPM might suffice for softer materials, while a higher RPM could be essential for efficiently cutting hard materials like granite or porcelain tile. Experts suggest experimenting with the RPM settings to find the right balance for various tile materials, as this can substantially improve cutting performance while minimizing tool wear.

Material-Specific Tooth Formulations

Choosing the right tooth formulation for the tile material you are working with can significantly impact cutting efficiency and accuracy. For hard materials like granite or porcelain tile, a finer tooth spacing is usually optimal. This is because such formulations can create more precise cuts, reducing the chance of chipping or unnecessary errors that impact the overall quality and time-efficiency of the task. In contrast, softer materials may benefit more from blades with wider tooth spacing, which allows for quicker material removal without compromising output quality. Selecting the most appropriate tooth formulation for your specific material type is crucial for optimizing efficiency and achieving high-quality results in tile cutting projects.

Maintenance for Long-Term Precision

Cleaning Diamond Particle Clogging

Ensuring the longevity and precision of diamond drill bits for glass and other materials requires regular cleaning to prevent particle clogging. Utilizing specialized cleaning agents helps maintain optimal blade functionality and effectiveness, ensuring the tools remain sharp and efficient. Neglecting this aspect of maintenance can lead to decreased cutting precision, potential damage, and a shortened lifespan of the tool.

Proper Blade Storage Practices

Proper storage is crucial to maximize the lifespan of diamond drill bits for granite. By storing these blades in a dry and cool environment, you can minimize rust and wear. Utilizing blade cases or racks further protects them from bending, chipping, or other types of damage, maintaining their integrity over time. Such practical storage practices are essential for avoiding unnecessary replacements and ensuring consistent performance.

Signs of Blade Wear & Replacement

Recognizing when your diamond drill bits for porcelain tile are nearing the end of their usability is key to maintaining quality and safety in cutting tasks. Signs such as decreased performance, visible chipping along the edges, or irregular cuts indicate that blades might need replacement. Industry guidelines recommend regular assessments for timely blade replacements, preventing accidents and ensuring tools perform optimally in cutting applications.

Choosing the Right Diamond Tool

Tile Material Hardness Considerations

Understanding the hardness of tile materials is crucial when selecting the appropriate diamond tool for your project. By examining the hardness, one can ensure the selection of tools that are suited to the material’s durability, such as a diamond drill bit for porcelain tile. This minimizes undue wear and tear while promoting efficient cutting. Utilizing testing methods like the Mohs scale can assist in making informed decisions, ensuring the diamond drill bit for granite is properly matched to the task at hand and extends its usability.

Project Scale & Frequency Factors

The scale and frequency of your tile-cutting projects can significantly influence your choice of tools. Larger projects necessitate more durable, diamond core drill bits capable of withstanding prolonged use. Those engaged in frequent tile cutting might find value in investing in high-quality diamond drill bits for granite or porcelain tile offering superior performance and longevity, ensuring cost-efficiency over time. By understanding the project's demands, one can budget appropriately and select tools that are optimal for both scale and frequency considerations.

Cost vs. Performance Tradeoffs

Evaluating the balance between cost and performance when selecting diamond tools is vital for ensuring long-term value. While cheaper diamond drill bits for glass might appear attractive initially, they can lead to higher expenses due to frequent replacements. On the other hand, investing in quality diamond core drill bit for concrete requires a higher upfront cost yet offers significant savings due to improved durability and reduced need for replacements. Consumer reviews and expert recommendations often provide valuable insights into the efficiency of these tools relative to their cost, guiding the investment toward better durability and performance.